Page 6 - Application Notebook - Hand Sanitizer Analysis

P. 6

Application Gas Chromatography

News

Alcohol Determination of Sanitizer Gel

in accordance with USP<611>

No. G333

United States Pharmacopeia (USP) General Chapters Analysis Conditions

<611> ALCOHOL DETERMINATION stipulates two Using the gas chromatograph Nexis™ GC-2030,

analytical methods for quantitating ethanol: one with ethanol in the standard solution and the sample

distillation and the other by gas chromatography. The solution were quantitated according to

latter (i.e. USP <611> Method II) further gives an USP<611>ALCOHOL DETERMINATION Method IIb. The

option of either using a packed column (Method II a) instrument configuration and analysis conditions for

or a capillary column (Method II b).

the this experiment are listed below in Table 1.

This article introduces a quantitative analysis of

ethanol in alcohol-based sanitizer gel according to Table 1 Instrument Configuration and Analysis Conditions

USP <611> Method II b.

Model : Nexis GC-2030 + AOC-20i Plus

N. Iwasa, T. Wada Detector : FID-2030 flame ionization detector

Column : SH-Rtx™-624 (30 m×0.53 mm I.D., d.f.= 3 µm)

Column Temperature : 50 °C (5 min) – 10 °C/min – 200 °C (4 min)

Total 24 mins

Preparation of Standard Solution and Sample Injection Temperature : 210 °C

Solution Injection Mode : Split

5 mL each of 2 %(v/v) ethanol *1 and 2 %(v/v) Split Ratio : 1: 5

: Linear velocity (He)

Carrier Gas Controller

acetonitrile *1 (internal standard), both in water, were Linear Velocity : 34 cm/sec

pipetted into a 25 mL volumetric flask, made up to Detector Temperature : 280 °C

FID H 2 Flow Rate : 32 mL/min

volume with water and vortex to prepare a 0.4 %(v/v) FID Make up Flow Rate : 24 mL/min (He)

standard solution. FID Air Flow Rate : 200 mL/min

Injection Volume : 0.2 µL

As a sample solution, a commercially available sanitizer Syringe : Elastic Syringe, AOC (P/N: 221-49548) *2

gel (ca. 80 %(v/v)) was first diluted with water to ca. 2

%(v/v) ethanol. To further bring down the concentration *2 When samples in aqueous solution are analyzed with a standard

to ca. 0.4 %(v/v), 5 mL of each of the prepared ca. 2 syringe for AOC-20i Plus, the plunger motion may become dull

%(v/v) sample and 2 %(v/v) acetonitrile were aliquoted during analysis, which affects repeatability. Using an elastic

syringe for AOC (P/N: 221-49548) equipped with a plunger made

into 25 mL volumetric flask and mixture was make up to

of titanium enables stable sample introduction.

volume with water.

*1 USP<611> specifies the use of USP Alcohol Determination-Alcohol In this analysis, a glass insert was specifically

RS (2 %(v/v) ethanol) and USP Alcohol Determination-Acetonitrile RS configured as shown in Fig.2 to meet the requirements

(2 %(v/v) acetonitrile) to prepare the standard solution. for the system suitability test(SST) in USP<611>. 20 mg

of deactivated glass wool was packed into a split glass

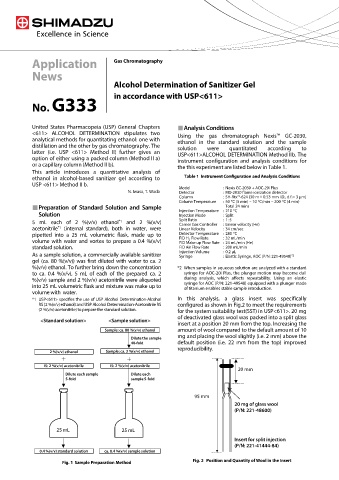

<Standard solution> <Sample solution>

insert at a position 20 mm from the top. Increasing the

Sample: ca. 80 %(v/v) ethanol amount of wool compared to the default amount of 10

mg and placing the wool slightly (i.e. 2 mm) above the

Dilute the sample

40-fold default position (i.e. 22 mm from the top) improved

reproducibility.

2 %(v/v) ethanol Sample: ca. 2 %(v/v) ethanol

+ +

IS: 2 %(v/v) acetonitrile IS: 2 %(v/v) acetonitrile

20 mm

Dilute each sample Dilute each

5-fold sample 5-fold

95 mm

20 mg of glass wool

(P/N: 221-48600)

25 mL 25 mL

Insert for split injection

(P/N: 221-41444-84)

0.4 %(v/v) standard solution ca. 0.4 %(v/v) sample solution

Fig. 2 Position and Quantity of Wool in the Insert

Fig. 1 Sample Preparation Method