Page 13 - Shimadzu TOC-4200

P. 13

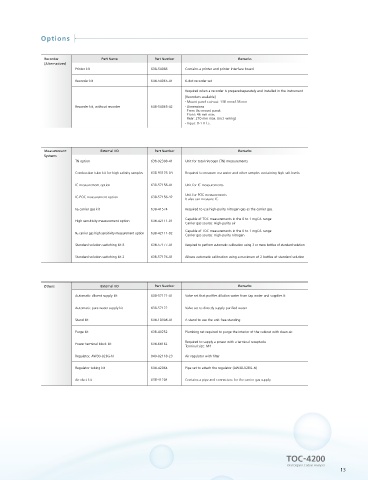

Options Options

Sampling Unit Part Name Part Number Remarks Recorder Part Name Part Number Remarks

(Alternatives) (Alternatives)

Sampling unit for samples with high suspended solids levels

Multi-stream suspended solids sampling unit 638-93206-41 to 46 Capable of switching between a maximum of 6 flow lines Printer kit 638-54066 Contains a printer and printer interface board.

Required sample flow rate: Approx. 10 L/min

Low-flow rate version of the multi-stream suspended solids sampling unit Recorder kit 638-54065-41 6-dot recorder set

Multi-stream suspended solids sampling unit LF 638-93207-41 to 46 Capable of switching between a maximum of 6 flow lines

Required sample flow rate: 1 to 2 L/min Required when a recorder is preparedseparately and installed in the instrument

Sampling unit for samples with high suspended solids levels [Recorders available]

Single stream suspended solids sampling unit 638-93186-41 Single stream only • Mount panel cut-out: 138 mm×138 mm

Required sample flow rate: 2 to 5 L/min Recorder kit, without recorder 638-54065-42 • Dimensions

Backwash strainer sampling unit (with pump) 638-41507-41 Sampling unit with automatic strainer backwashing using air From the mount panel:

Front: 46 mm max.

Backwash strainer sampling unit (without pump) 638-41507-42 Single stream only Rear: 270 mm max. (incl. wiring)

Backwash strainer sampling unit F (with pump) 638-41507-43 • (with pump): Backwashing air is supplied from the internal pump to • Input: 0-1 V f.s.

the supply cylinder to reduce the air consumption.

Backwash strainer sampling unit F (without pump) 638-41507-44

• (without pump): Backwashing air is supplied from carrier gas source.

Backwash strainer sampling unit E (with pump) 638-41507-45

• “F”: With float sensor

Backwash strainer sampling unit E (without pump) 638-41507-46 This can detect if the sample water flow is interrupted.

Backwash strainer sampling unit EF (with pump) 638-41507-47 • ”E”: No disinfection by chlorine agent water treat

Required sample flow rate: 1 to 3 L/min Measurement External I/O Part Number Remarks

Backwash strainer sampling unit EF (without pump) 638-41507-48

Systems

Sampling unit for measurement of comparatively clean samples TN option 638-92308-41 Unit for total nitrogen (TN) measurements

Multi-stream sample switching unit 638-93193-41 to 46 Capable of switching between a maximum of 6 flow lines

Required sample flow rate: 1 to 3 L/min

Combustion tube kit for high salinity samples 638-93176-04 Required to measure sea water and other samples containing high salt levels.

Sampling unit for measurement of comparatively clean samples

Single-flow-line (-01) and double-flow-line (-02) versions are available.

Sample stream kit 638-41582-01, 02 As the second flow line uses the off-line port, off-line measurement functions are IC measurement option 638-57156-41 Unit for IC measurements

not available if the double-flow-line version (-02) is used.

Required sample flow rate: 1 to 3 L/min Unit for POC measurements

IC-POC measurement option 638-57156-42

Expansion set to use the single-flow-line version of the sample stream kit as a It also can measure IC.

double-flow-line version

Sample stream additional kit 638-41582-03

As the second stream uses the off-line port, off-line measurement functions are N2 carrier gas kit 638-41574 Required to use high-purity nitrogen gas as the carrier gas.

not available if the double-flow-line version (-02) is used.

Capable of TOC measurements in the 0 to 1 mgC/L range

High sensitivity measurement option 638-42111-01

Carrier gas source: High-purity air

Capable of TOC measurements in the 0 to 1 mgC/L range

N2 carrier gas high sensitivity measurement option 638-42111-02

External I/O External I/O Part Number Remarks Carrier gas source: High-purity nitrogen

Terminal (2) expansion kit Standard solution switching kit 8 638-57177-41 Required to perform automatic calibration using 3 or more bottles of standard solution

Optional terminal (2) kit 638-79078-41 Expanding contents Analog output: 2 channels

Contact input: 8 channels (For control 2 and 3 flow lines)

Standard solution switching kit 2 638-57176-41 Allows automatic calibration using a maximum of 2 bottles of standard solution

Terminal (3) expansion kit

Required the option terminal (2) kit

Optional terminal (3) kit 638-79079-41

Expanding contents Contact output: 26 channels

Contact input: 8 channels (For control 4 to 6 flow lines)

The kit for expanding Option terminal (2) kit and Option terminal (3) kit

Optional terminal (2) (3) kit 638-79080-41

simultaneously Others External I/O Part Number Remarks

Each set offers two analog outputs. Automatic diluent supply kit 638-57171-41 Valve set that purifies dilution water from tap water and supplies it

Required for five or more outputs.

Up to four sets can be added (making 12 outputs maximum).

Analog output board 638-79084-41

Requires the PCB fixing bracket, terminal (638-84218), Automatic pure water supply kit 638-57172 Valve set to directly supply purified water

and optional terminal (2) kit (638-79078).

(Isolated outputs, load resistance: 500 max.)

Stand kit 638-10308-41 A stand to use the unit free-standing

For flow rate signal inputs (3 inputs)

Requires the PCB fixing bracket, terminal (638-84218),

Analog input board 638-79083-41

and optional terminal (2) kit (638-79078). Purge kit 638-40252 Plumbing set required to purge the interior of the cabinet with clean air.

(Isolated inputs, CH-CH is non-isolated. Load resistance: 100 )

Separate programming is required to use the protocol conversion functions. Power terminal block kit 638-68162 Required to supply a power with a terminal receptacle

Data converter kit 638-79077-41 The RS-232C set (638-66228) is required for communications. Terminal size: M4

Requires the PCB fixing bracket, main (638-84217).

Regulator, AW30-02BG-N 040-82118-23 Air regulator with filter

PCB retaining fitting, terminal 638-84218 Required to expand the analog input/output boards ( * ) .

Regulator tubing kit 638-42064 Pipe set to attach the regulator (AW30-02BG-N)

PCB retaining fitting, main 638-84217 Required to expand boards other than the analog input/output boards ( * ) .

Air duct kit 638-41204 Contains a pipe and connectors for the carrier gas supply.

RS-232C kit 638-66228 D-sub 9 pin (male)

Web monitor unit set 638-79077-42 Required to use web-based monitoring.

(*) One required per instrument, even when adding multiple boards

TOC-4200

Total Organic Carbon Analyzer

12 13