Page 3 - Shimadzu ON-LINE TOC-VCSH

P. 3

This on-line TOC analyzer offers both high sensitivity

and superior oxidation performance for organic materials.

On-line Models Combustion catalytic oxidation/NDIR method

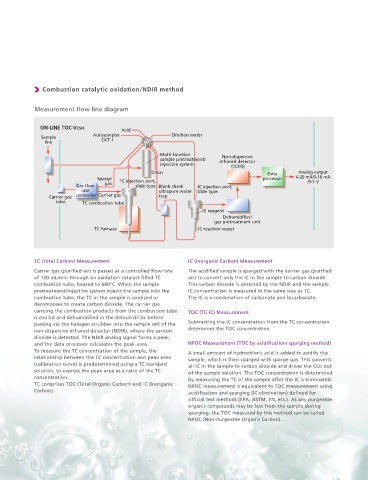

ON-LINE TOC-VCSH Measurement flow line diagram

A function for continuous automatic high-sensitivity measurement of organic

measurement has been added to the ability of substances. The On-line TOC-VCSH can be used for ON-LINE TOC-VCSH Acid

the combustion catalytic oxidation/NDIR TOC-V continuous automatic high-sensitivity monitoring Sample Autosampler Dilution water

Series to perform high-performance, of samples such as pure water and tap water. line OCT-I

Multi-function Non-dispersive

sample pretreatment/ infrared detector

injection system (NDIR)

Drain Data Analog output

Sparge TC injection port, processor 4-20 mA/0-16 mA

gas /0-1 V

Gas flow slide type Blank check IC injection port,

rate ultrapure water slide type

Extremely wide range from 4 µg/L to 25,000 mg/L for Carrier gas controller Carrier gas trap

applications from ultrapure water to highly contaminated inlet

water. TC combustion tube

IC reagent

Combination of highly sensitive NDIR with a high-volume sample combustion Dehumidifier/

system achieves sub-10 µg/L level TOC analysis. gas pretreatment unit

Specify the blank check program to automatically conduct the blank check TC furnace IC reaction vessel

by creating and analyzing ultrapure water inside the system.

High concentration samples are analyzed by diluting to 25,000 mg/L the

built-in automatic dilution function.

Combines Combustion Catalytic Oxidation at 680°C and NDIR Support Software for Pharmaceutical Water Management TC (Total Carbon) Measurement IC (Inorganic Carbon) Measurement

Method Applications

Carrier gas (purified air) is passed at a controlled flow rate The acidified sample is sparged with the carrier gas (purified

Combustion catalytic oxidation at 680°C oxidizes even persistent or insoluble The On-line TOC-VCSH incorporates software for automatically performing tests of 150 mL/min through an oxidation catalyst-filled TC air) to convert only the IC in the sample to carbon dioxide.

organic compounds. This method accurately measures any type of organic specified by Japanese Pharmacopeia (resolution test) and USP (system suitability combustion tube, heated to 680°C. When the sample This carbon dioxide is detected by the NDIR and the sample

substance not affected by interfering substances or the sample properties such test). Combining the On-line TOC-VCSH with an OCT-1 (optional) enables fully

as pH or conductivity. automatic testing; setting the reagent is the only requirement. pretreatment/injection system injects the sample into the IC concentration is measured in the same way as TC.

combustion tube, the TC in the sample is oxidized or The IC is a combination of carbonate and bicarbonate.

decomposes to create carbon dioxide. The carrier gas

Easy Maintenance

carrying the combustion products from the combustion tube TOC (TC-IC) Measurement

Combustion catalytic oxidation at 680°C eliminates the need for oxidizing is cooled and dehumidified in the dehumidifier before

reagents, saving the tasks of procuring and preparing reagents. No special passing via the halogen scrubber into the sample cell of the Subtracting the IC concentration from the TC concentration

draining operations are needed. non-dispersive infrared detector (NDIR), where the carbon determines the TOC concentration.

dioxide is detected. The NDIR analog signal forms a peak,

Off-line Measurement Functions and the data processor calculates the peak area. NPOC Measurement (TOC by acidification/ sparging method)

To measure the TC concentration of the sample, the

A dedicated on-line measuring port is provided for easily conducting A small amount of hydrochloric acid is added to acidify the

interrupting analyses. The optional OCT-1 allows the automatic measurement of relationship between the TC concentration and peak area sample, which is then sparged with sparge gas. This converts

up to 15 samples. (calibration curve) is predetermined using a TC standard all IC in the sample to carbon dioxide and drives the CO2 out

solution, to express the peak area as a ratio of the TC of the sample solution. The TOC concentration is determined

Wide Variety of TOC Measurement Methods concentration. by measuring the TC of the sample after the IC is eliminated.

TC comprises TOC (Total Organic Carbon) and IC (Inorganic

NPOC, IC, TC and TOC (TC-IC) measurements are possible with the On-line Carbon). NPOC measurement is equivalent to TOC measurement using

TOC-VCSH. TN measurement is also possible by adding an optional product. TOC acidification and sparging (IC elimination) defined for

and TN can be measured simultaneously. official test methods (EPA, ASTM, EN, etc.). As any purgeable

organic compounds may be lost from the sample during

sparging, the TOC measured by this method can be called

Main Applications NPOC (Non-Purgeable Organic Carbon).

Management of pharmaceutical water

Management of ultrapure and recycled water for the semiconductor industry

Management of mains water

Impurity contamination management for all types of water used at plants (cooling water, recycled water, and boiler water)