Page 11 - Shimadzu HITS-X Series

P. 11

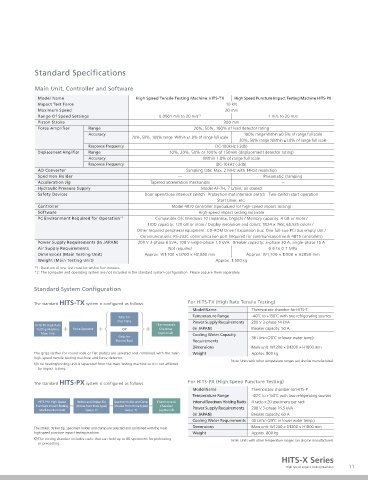

Standard Specifications

Main Unit, Controller and Software

Model Name High Speed Tensile Testing Machine HITS-TX High Speed Puncture Impact Testing Machine HITS-PX

Impact Test Force 10 kN

Maximum Speed 20 m/s

Range Of Speed Settings 0.0001 m/s to 20 m/s *1 1 m/s to 20 m/s

Piston Stroke 300 mm

Force Amplifier Range 20%, 50%, 100% of load detector rating

Accuracy 100% range:Within ±0.5% of range full scale

20%, 50%, 100% range :Within ±1.0% of range full scale

20%, 50% range :Within ±1.0% of range full scale

Response Frequency DC-100kHz (-3db)

Displacement Amplifier Range 10%, 20%, 50% or 100% of 150mm (displacement detector rating)

Accuracy Within 1.0% of range full scale

Response Frequency DC-10kHz (-3db)

AD Converter Sampling rate: Max. 2 MHz with 14-bit resolution

Specimen Holder - Pneumatic clamping

Acceleration Jig Tapered acceleration mechanism -

Hydraulic Pressure Supply Model AF-7H, 7 L/min, air cooled

Safety Devices Door open/close interlock switch Protection mat interlock switch Two-switch start operation

Start timer, etc.

Controller Model 4870 controller (specialized for high-speed impact testing)

Software High-speed impact testing software

PC Environment Required for Operation *2 Compatible OS: Windows 10 (Japanese, English) / Memory capacity: 4 GB or more /

HDD capacity: 120 GB or more / Display resolution and colors: 1024 × 768, 65,535 colors /

Other required peripheral equipment: CD-ROM Drive / Expansion bus: One full-size PCI bus empty slot /

Communications: RS-232C communication port (required for communication with 4875 controllers)

Power Supply Requirements (In JAPAN) 200 V 3-phase 6 kVA, 100 V single-phase 1.5 kVA Breaker capacity: 3-phase 30 A, single-phase 15 A

Air Supply Requirements Not required 0.6 to 0.7 MPa

Dimensions (Main Testing Unit) Approx. W1,100 × D700 × H2,850 mm Approx. W1,100 × D900 × H2850 mm

Weight (Main Testing Unit) Approx. 1,500 kg

*1: Duration of one test must be within five minutes.

*2: The computer and operating system are not included in the standard system configuration. Please acquire them separately.

Standard System Configuration

The standard HITS-TX system is configured as follows. For HITS-TX (High Rate Tensile Testing)

Model Name Thermostatic chamber for HITS-T

Grip for Temperature Range -40˚C to +150˚C with two refrigerating sources

Flat Plate Power Supply Requirements 200 V 3-phase 14 kVA

HITS-TX High Rate Thermostatic

Testing Machine Force Detector or Chamber (In JAPAN) Breaker capacity: 50 A

Main Unit (optional)

Grip for Cooling Water Capacity 36 L/min (20˚C or lower water temp)

Round Rod Requirements

Dimensions Main unit: W1200 × D1200 × H1800 mm

The grips (either for round rods or flat plates) are selected and combined with the main Weight Approx. 800 kg

high-speed tensile testing machine and force detector.

Note: Units with other temperature ranges can also be manufactured.

The heating/cooling unit is separated from the main testing machine so it is not affected

by impact testing.

The standard HITS-PX system is configured as follows. For HITS-PX (High Speed Puncture Testing)

Model Name Thermostatic chamber for HITS-P

Temperature Range -40˚C to +150˚C with two refrigerating sources

HITS-P10 High Speed Striker and Striker Tip Specimen Holder and Clamp Thermostatic Internal Specimen Holding Racks 4 racks x 20 specimens per rack

Puncture Impact Testing (choose from three types) (choose from three types) Chamber

Machine Main Unit (see p. 7) (see p. 7) (optional) Power Supply Requirements 200 V 3-phase 16.5 kVA

(In JAPAN) Breaker capacity: 60 A

Cooling Water Requirements 40 L/min (20˚C or lower water temp.)

The striker, striker tip, specimen holder and clamp are selected and combined with the main Dimensions Main unit: W1200 × D1200 × H1800 mm

high speed puncture impact testing machine. Weight Approx. 800 kg

The testing chamber includes racks that can hold up to 80 specimens for preheating Note: Units with other temperature ranges can also be manufactured.

or precooling.

HITS-X Series

High Speed Impact Testing Machines 11