Page 8 - Shimadzu EDX-LE

P. 8

Fully Equipped with Essential Functions

All-in-One Design Includes All Functions Required for RoHS/ELV Screening

Overall RoHS/ELV analysis performance is tied to the smooth coordination of a variety of analytical Qualitative-Quantitative Analysis *Additional function kit is required.

systems, creating a synergistic effect. The EDX-LE can perform qualitative analysis and

For this reason, EDX-LE standard equipment includes all the functions required for RoHS/ELV analysis, non-standard quantitative analysis based on the FP method. -FeKa

providing users with the optimal RoHS/ELV screening System. This means it can be used to analyze foreign substances or

differentiate between different materials. X-ray Fluorescence Intensity -CrKa

Stainless Steel (FP Method)

-V Ka -CrKb MnKa -FeKb -NiKa -CuKa -NiKb -CuKb -Moka -Mokb -RhKa -RhKb Quantitative Analysis Results for

5 10 15 20 25

Obtaining highly reliable analytical results Organize measurement results in a list [keV]

Qualitative Profile of Stainless Steel

Calibration Curve Method and FP Method List Creation Function

To improve the reliability of analysis results for elements List data stored in Excel format.

specified by the RoHS/ELV directive, the elements are

analyzed using the calibration curve method and standard Matching (Steel Type Identification, Product Identification) *Additional function kit is required.

sample (check sample) provided with the instrument. (The Comparing measurement data to a data library of steel types

Fundamental Parameter (FP) method is used to analyze allows automatic identification for everything from materials

some RoHS elements in metal samples.) Any other elements closest to the sample, to the 10th position on the library list.

detected are analyzed using the FP method, which uses In addition to matching by intensity, matching by content is

theoretical calculations to provide additional information. also available if the user creates and registers libraries of

concentrations and elements.

Compensates for the influence of

differences in shape of actual samples Note that this requires installation of Microsoft Office Excel before use. Intensity Matching Results Element and Content

on analysis results Registration Window

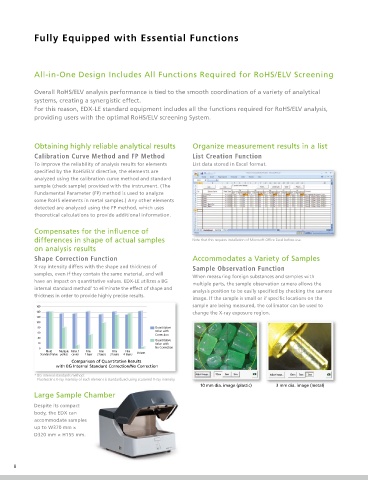

Shape Correction Function Accommodates a Variety of Samples

X-ray intensity differs with the shape and thickness of Sample Observation Function Thin-Film Analysis *Additional function kit is required.

samples, even if they contain the same material, and will When measuring foreign substances and samples with The Film FP method obtains not only single layer, but multilayer film thickness, composition, and deposit volume.

have an impact on quantitative values. EDX-LE utilizes a BG multiple parts, the sample observation camera allows the It is also well-suited to the measurement of Pb contained in plating. (Information on the layer order (including base) and the

internal standard method to eliminate the effect of shape and analysis position to be easily specified by checking the camera constituent elements is necessary.)

*

thickness in order to provide highly precise results.

image. If the sample is small or if specific locations on the

160 sample are being measured, the collimator can be used to Result of Qualitative Analysis

140 change the X-ray exposure region. P Ni Pb

120

100 −P Ka −Nika −AuLb1

80 Quantitative

Value with 50 nm

60

Correction

40

Quantitative

20 Value with X-ray Fluorescence Intensity X-ray Fluorescence Intensity X-ray Fluorescence Intensity 40 nm

0 No Correction

Mold Multiple Pellet 1 Film Film Film Film Variant

Standard Value pellets center 1 layer 2 layers 3 layers 4 layers

Comparison of Quantitative Results X-ray Fluorescence Intensity 30 nm

with BG Internal Standard Correction/No Correction −PbLb1

* BG inter nal standar ds method:

* BG internal standards method:

Fluorescent X-ray intensity of each element is standardized using scattered X-ray intensity.

Fluorescent X-ray intensity of each element is standardized using scattered X-ray intensity. 20 nm

1 2 3 [keV] 7 8 [keV] 12 13 [keV]

10 mm dia. image (plastic) 3 mm dia. image (metal)

* Trace amounts of lead as a stabilizer detected

Large Sample Chamber Result of Quantitative Analysis 10 nm

Layer Info Analyte Result (Std. Dev.) Proc.-Calc. Line

Despite its compact

Total

body, the EDX can Elem. Quan

Quan

Elem.

accommodate samples Elem. Quan 11.00 11.50 12.00 [keV]

up to W370 mm × Elem. Fix Au evaporated film

D320 mm × H155 mm.

Example of Measurement of Electroless Ni-P Plating Example of Thickness Measurement for Thin-Film Sample

EDX-LE

8 Energy Dispersive X-ray Fluorescence Spectrometer 9