Page 10 - Shimadzu ICPS-7510 - New

P. 10

Specifications Installation

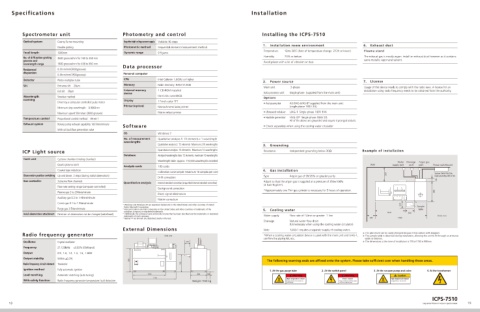

Spectrometer unit Photometry and control Installing the ICPS-7510

Optical system Czerny-Turner mounting Negative high voltage power supply Variable 16 steps

1. Installation room environment 6. Exhaust duct

Double grating Photometric method Sequential element measurement method

Temperature 18 to 28˚C (Rate of temperature change: 2˚C/h or lower) Plasma stand

Focal length 1000mm Dynamic range 9 figures

No. of diffraction grating 3600 grooves/mm for 160 to 458 mm Humidity 70% or below The exhaust gas is mostly argon. Install an exhaust duct however as it contains

grooves and Avoid places with a lot of vibration or dust. some metallic vapor and solvent.

wavelength range 1800 grooves/mm for 458 to 850 mm

Data processor

Reciprocal 0.22nm/mm(3600grooves)

dispersion Personal computer

0.44nm/mm(1800grooves)

Detector Photo-multiplier tube CPU Intel Celeron 1.6GHz or higher

2. Power source 7. License

Slit Entrance slit 20µm Memory Main memory: RAM 512MB

Main unit 3-phase Usage of this device needs to comply with the radio laws. A license for an

Exit slit 30µm External memory 1 CD-ROM installed installation using radio frequency needs to be obtained from the authority.

device Data processor unit Single phase (supplied from the main unit)

Wavelength Sine-bar method Hard disk over 80GB Options

scanning Display

Driven by a computer controlled pulse motor 17 inch color TFT • Autosampler AS-9/AS-6/AS-8T supplied from the main unit.

Printer (option) (single phase 100V 3A)

Minimum step wavelength 0.0002nm Monochrome laser printer

Maximum speed 50nm/sec (3600 grooves) Matrix inkjet printer • Ultrasound nebulizer UAG-1 Single phase 100V 10A

Temperature control Proportional control method 38 ±0.1 • Hydride generator HVG-ICP Single phase 100V 2A

All of the above are grounded and require 3 pronged sockets.

Exhaust system Rotary pump exhaust capability 160 liters/minute

Software • Check separately when using the cooling water circulator

With oil backflow prevention valve

OS Windows 7

No. of measurement Qualitative analysis 1: 72 elements x 1 wavelength

wavelengths

Qualitative analysis 2: 72 elements Maximum 216 wavelengths 3. Grounding

ICP Light source Quantitative analysis: 72 elements Maximum 72 wavelengths Resistance independent grounding below 30 Example of installation

Database Analyzed wavelengths data: 72 elements, maximum 16 wavelengths

Torch unit Cyclone chamber (misting chamber)

Wavelength table: Approx. 110,000 wavelengths recorded Water Drainage Argon gas

Quartz plasma torch Wall supply port port port Power switchboard

Analysis cards 100 cards

Coaxial type nebulizer 4. Gas installation

Calibration curve sample Maximum 16 samples per card 3-phase 200V/220V 20A,

Observation position switching Up and down, 2 steps (during radial observation) Type Argon gas of 99.95% or greater purity 300 single grounding 30 or less

Drift correction

Gas controller 3 plasma flow channels Adjust so that the argon gas is supplied at a pressure of 350±10kPa 144

Quantitative analysis Internal standard correction (sequential internal standard correction)

Flow rate setting range (computer controlled) (3.5±0.1kg/cm 2 ).

Background correction *Approximately one 7m 3 gas cylinder is necessary for 5 hours of operation.

Plasma gas 2 to 20liters/minute 680

Blank signal elimination

Auxiliary gas 0.2 to 1.4liters/minute

Matrix correction

Carrier gas 0.1 to 1.5liters/minute

* Windows and Windows XP are registered trademarks in the United States and other countries of United 233

States Microsoft Corporation. Sample

Purge gas 3.5liters/minute * Intel and Celeron are Intel Corporation in the United States and other countries or trademarks of the 5. Cooling water table

subsidiary company or registrered trademarks. 1042

Axial observation attachment Direction of observation can be changed (radial/axial) * Additionally, the company name and product name that has been described are the trademarks or registered 308

trademarks of each company. Water supply Flow rate of 1L/min or greater 1 line Units: mm

* Neither TM nor ® mark are desbribed clearly in the text. 100 1785

Drainage Natural water flow drain

(Unnecessary when using the cooling water circulator)

External Dimensions Note UAG-1 requires a separate supply of cooling water.

Radio frequency generator Units: mm *When a cooling water circulation device is used with the main unit and UAG-1, * The placement can be easily changed because it has casters with stoppers.

The sample table is detached during installation, allowing the unit to fit through an entrance

*

confirm the piping kit, etc. width of 800mm.

Oscillator Crystal oscillator 233 * The dimensions at the time of installation is 735 × 1785 × 998mm.

Frequency 27.120MHz ±0.05% (ISM band) 200

Output 0.8, 1.0, 1.2, 1.4, 1.6, 1.8kW

Output stability Within ±0.3%

998 The following warning seals are affixed onto the system. Please take sufficient care when handling these areas.

Radio frequency circuit element Transistor 752

Ignition method Fully automatic ignition 1. At the gas purge tube 2. At the switch panel 3. At the vacuum pump and valve 4. At the transformer

Load matching Automatic matching (auto tuning) 1350 680 144 Warning Warning Caution

1785 High-temperature hazard Shock hazard High-temperature hazard

With safety function Radio frequency generator temperature fault detection Weight: 550 kg Danger of burns. Do not touch or Danger of electric shock.Turn power Danger of burns. Do not touch.

look through. OFF prior to opening cover.

ICPS-7510

18 Sequential Plasma Emission Spectrometer 19