Page 5 - Shimadzu HITS-X Series

P. 5

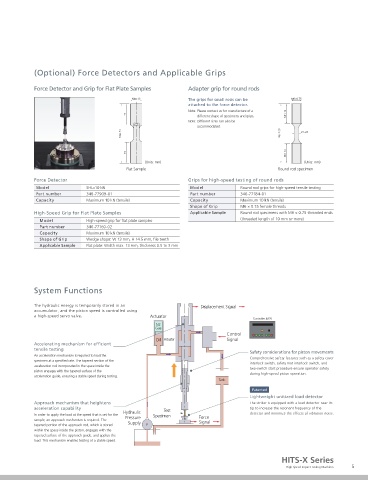

(Optional) Force Detectors and Applicable Grips

Force Detector and Grip for Flat Plate Samples Adapter grip for round rods

Max.13 The grips for small rods can be M6×0.75

attached to the force detector.

Note: Please contact us for manufacture of a

15 Min.10

different shape of specimens and grips.

Note: Different sizes can also be

2~6

accommodated.

Max.70 Max.100 ø1~ø3

Min.10

15

(Units: mm) (Units: mm)

Flat Sample Round rod specimen

Force Detector Grips for high-speed testing of round rods

Model SHL−10 kN Model Round rod grips for high-speed tensile testing

Part number 346-77909-01 Part number 346-77184-01

Capacity Maximum 10 kN (tensile) Capacity Maximum 10 kN (tensile)

Shape of Grip M6 × 0.75 female threads

High-Speed Grip for Flat Plate Samples Applicable Sample Round rod specimens with M6 × 0.75 threaded ends

Model High-speed grip for flat plate samples (threaded length of 10 mm or more)

Part number 346-77160-02

Capacity Maximum 10 kN (tensile)

Shape of Grip Wedge shape: W 13 mm, H 14.5 mm, file teeth

Applicable Sample Flat plate: Width max. 13 mm, thickness 0.5 to 3 mm

System Functions

The hydraulic energy is temporarily stored in an Displacement Signal

accumulator, and the piston speed is controlled using

a high-speed servo valve. Actuator

Controller 4870

N2

Gas

Control

Oil Actuator Signal

Accelerating mechanism for ef cient

tensile testing Safety considerations for piston movements

An acceleration mechanism is required to load the Comprehensive safety features such as a safety cover

specimen at a speci ed rate. The tapered section of the

interlock switch, safety mat interlock switch, and

acceleration rod incorporated in the space inside the two-switch start procedure ensure operator safety

piston engages with the tapered surface of the

acceleration guide, ensuring a stable speed during testing. during high-speed piston operation.

Tank

Patented

Lightweight unitized load detector

Approach mechanism that heightens The striker is equipped with a load detector near its

acceleration capability tip to increase the resonant frequency of the

Hydraulic Test detector and minimize the effects of vibration noise.

In order to apply the load at the speed that is set for the Specimen

sample, an approach mechanism is required. The Pressure Force

Signal

tapered portion of the approach rod, which is stored Supply P

within the space inside the piston, engages with the

tapered surface of the approach guide, and applies the

load. This mechanism enables testing at a stable speed.

HITS-X Series

High Speed Impact Testing Machines 5