Constant Test Force Extrusion Type Capillary Rheometer Flowtester

This device evaluates viscosity properties from the relationship to temperature, pressure, and flow velocity, etc., for flowable materials. It demonstrates its power in research and development, production processes, and quality control for various flowable materials such as thermoplastic resins, thermosetting resins, toner, composite materials, ceramics and rubbers.

Efficient Testing with a Reliable Evaluation Method

High test force precision, provided by a weight-based constant test force loading system, enables high measurement reproducibility and test efficiency. In addition to increased operability to improve testing efficiency, accurate temperature measurement and stable control are provided through a reliable temperature control system.

Evaluation of Softening and Flow Beginning Temperature Using Constant Heating Rate Testing

Testing methods include a constant temperature method a constant heating rate method. The constant heating rate method permits measurement of resin softening temperature and flow beginning temperature to determine shear rate and viscosity at each temperature and cannot be conducted using other capillary type rheometers.

Viscosity Evaluation of Thermosetting Resin

Weight-based constant test force extrusion is used to measure the amount of piston movement (movement speed), which is used to determine viscosity. Highly reproducible measurements of fluidity of thermosetting resins, which cure rapidly due to heating, can be determined due to the highly precise temperature control and the range of test forces available.

A Combination of Safety and Functionality

【High Test Force Precision and Wide Pressure Range up to 50 MPa】

High test force precision is obtained by the weight-based fixed test force loading system. In addition, since the test force can be set over a wide range, measurement can be conducted using a pressure that is close to actual injection molding conditions. Under high pressure, which cannot be obtained using the melt flowrate (MFR) measurement method (up to 21.6 kg/about 2 MPa), data that is useful for molding can be obtained.

【Wide Test Temperature Range from 20°C above Room Temperature to 400°C】

The wide temperature range makes it possible to measure a wide range of materials, including engineering plastics. Furthermore, by using the optional low-temperature test attachment and high-temperature heating attachment, the applicable temperature range can be expanded.

【High-Precision Temperature Control System】

The temperature control system developed specifically for the flowtester provides accurate measurement and stable control of the temperature, which is one of the most important qualities of a capillary rheometer.

【Focus on Ease of Use and Safety】

Since the furnace can be rotated up to 90° to the left and right, little effort is required for die replacement and furnace cleaning. In addition, a safety cover prevents inadvertent contact with the furnace and piston during testing.

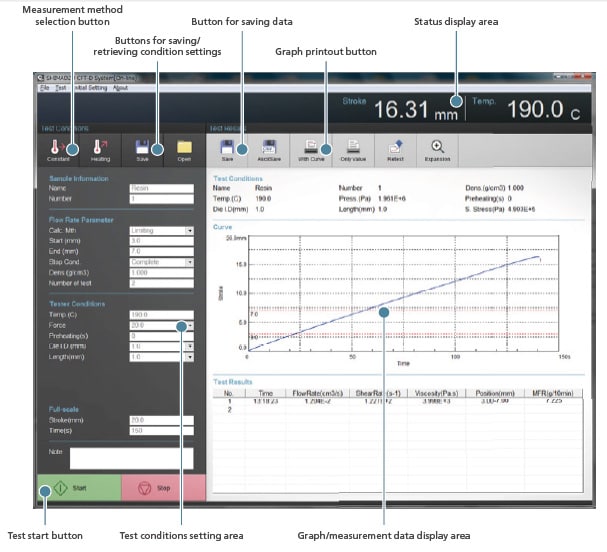

Natural, Easy Test Flow

The software, which is configured to match the operation flow, offers a smooth progression through setting of conditions, starting and stopping the test, data acquisition, data storage, and reanalysis of stored data.

Setting Up Test Conditions to Storing Data – All on a Single Window

All operations associated with selecting the test method (either constant temperature or constant heating rate method), setting of test conditions, and output from test start to test results can be accomplished effortlessly. Data is automatically saved, and can be re-analyzed at any time after the test using off-line software.