The USF-2000A implements materials fatigue testing at 20 kHz. Consequently, it is possible to evaluate 109 to 1010 order fatigue strength, where it had been difficult to obtain data before. Also, data for 107 cycles can be obtained in about ten minutes.

USF-2000A Features

- Accelerated evaluation of the fatigue life of metals and materials is possible at 20 kHz cycle speed. Even 1010 cycle tests are completed in a mere six days.

- Significant stress can be produced by testing under resonance conditions, and furthermore is economical.

- Constant stress amplitude control is possible via the controller (provided) with the PC.

- Optimal for long-life evaluation of materials and high-speed vibration replication experiments.

- The test system is extremely compact, allowing it to be installed anywhere.

- The Windows software provided can be used for easy testing from design of resonance specimens through to actual testing.

20 kHz Fatigue Testing Ultra Efficient for Gigacycle Testing Also for Analyzing Inclusions in Metals

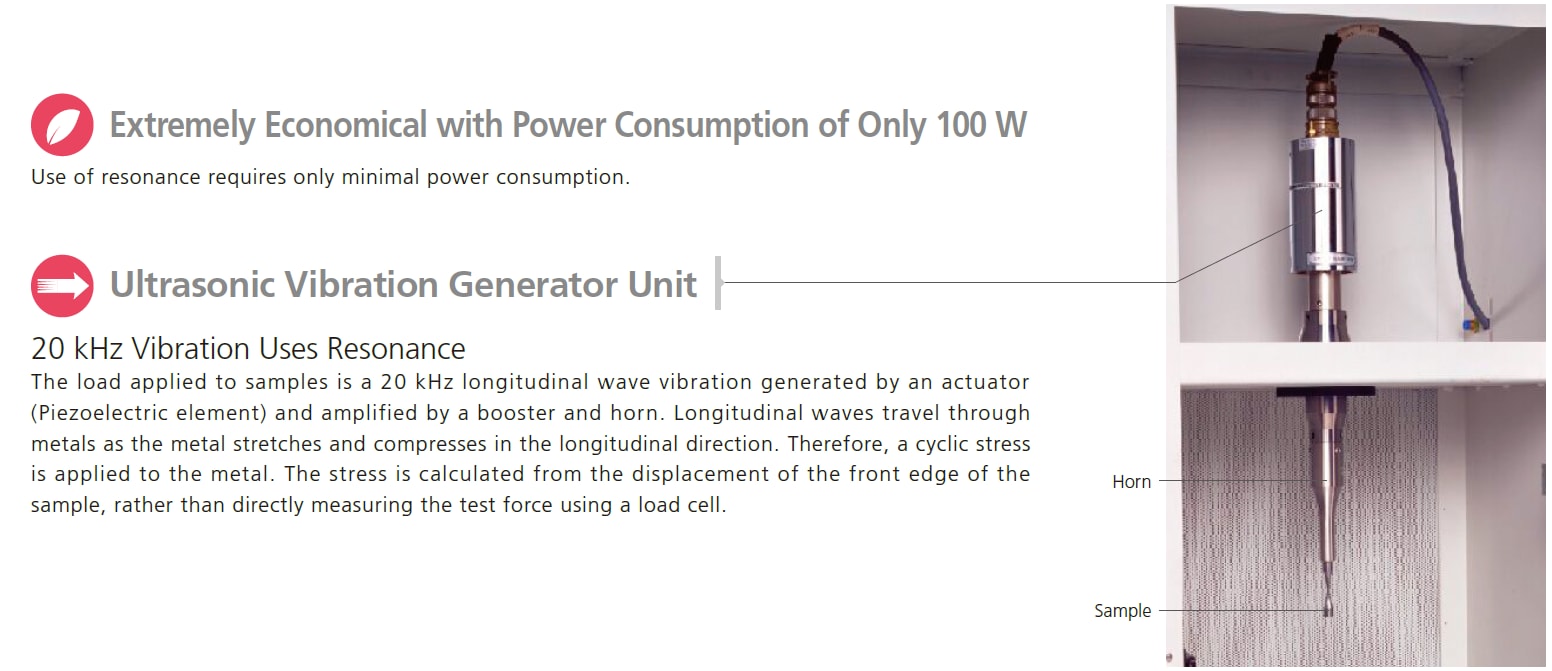

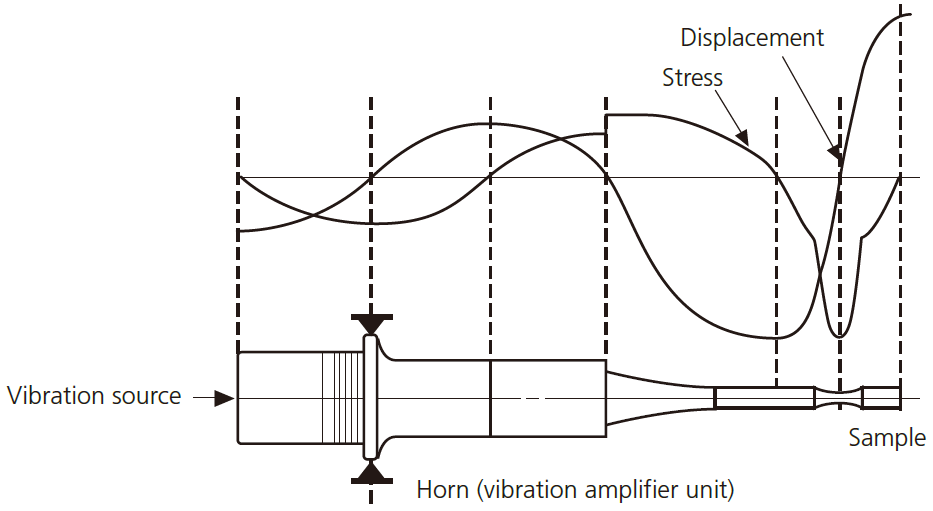

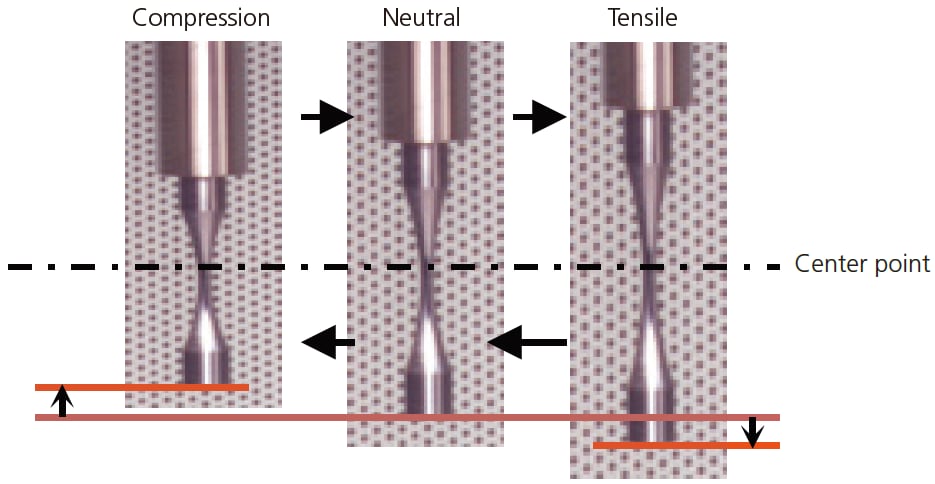

This ultrasonic fatigue testing system achieves a vibration rate of 20 kHz by applying a vibration generated by a Piezoelectric element and amplified by a horn. This not only significantly reduces cycle times, it also helps discover microscopic defects and inclusions in high-strength steel materials, which can cause fatigue fractures at the megacycle level.

Capable of Testing 1000 MPa Class Steel Material

High stresses can be generated by performing tests at resonance frequencies. With a 20 kHz cycle capacity, this system is able to accelerate fatigue life evaluations of metals and other materials. It is perfect for long service life evaluation of materials or high-speed vibration testing.

Operating Principle of the Ultrasonic Fatigue Testing System

Testing at Resonance Frequency