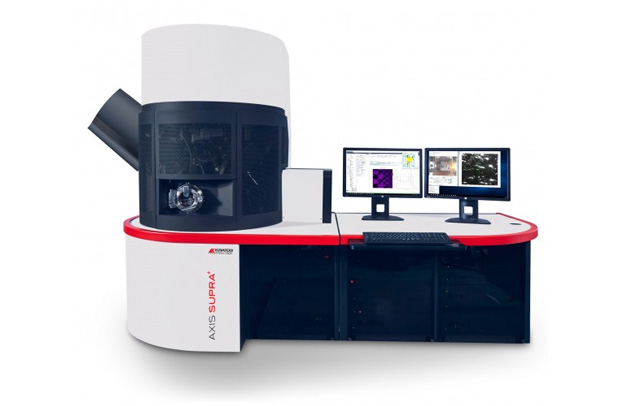

Our next generation XPS, the AXIS Supra+, with enhanced performance over its predecessor, combines market leading spectroscopic and imaging capabilities with unrivalled automation to ensure high sample throughput and ease of use. Unrivalled large area spectroscopic performance allows photoelectron spectra to be acquired. Fast, high spatial resolution XPS imaging reveals the lateral distribution of surface chemistry and aids further characterisation with selected area analysis.

Improved Performance

The AXIS Supra+ is set apart from any other spectrometer by complete automation through computer control of sample handling and instrument parameters. Unattended sample holder transfer and exchange during analysis is achieved through coordination of the Flexi-lock sample magazine and sample analysis chamber autostage.

ESCApe integrated acquisition and processing software allows the AXIS Supra+ to perform to its maximum capability and provides an easy interface with the spectrometer.

Capabilities of the AXIS Supra+

Large area, high sensitivity XPS

The AXIS Supra+ is optimised for chemical state X-ray photoelectron spectroscopy. Efficient collection of photoelectrons combined with high transmission electron optics ensures unrivalled sensitivity and resolution at large analysis areas. As well as conventional scanned acquisition, spectra may be acquired in fast, unscanned snap-shot mode in less than a second making use of the 128 channel Delay-Line Detector (DLD).

Key capabilities include:

- Easy detection of light elements

- Excellent signal-to-noise, even at low concentrations

- Fast data acquisition

- Scanned or snap-shot spectral acquisition modes.

High energy resolution

The fundamental requirement of any spectrometer is the best possible energy resolution. High energy resolution, where the spectrometer does not contribute to the broadening of the photoemission peaks, is critical for the accurate measurement of small chemical shifts. The AXIS Supra+ has a large 500 mm Rowland circle monochromated Al Kα X-ray source and optimised electron optics ensuring excellent chemical resolution.

Advantages of high spectral energy resolution include:

- Unambiguous identification of chemical shifts

- Guaranteed energy resolution on insulating and conducting samples.

Fast parallel imaging

The lateral distribution of elements or chemistry at the surface is measured by XPS imaging. The AXIS Supra+ acquires fast, high spatial resolution parallel images. Parallel image acquisition has the advantage that it is significantly faster and achieves higher spatial resolution than the more conventional rastered beam approach. Parallel imaging may also be combined with stage movements to acquire a ‘stitched’ image, capable of generating images over several millimetres with spatial resolution of several microns.

Capabilities provided by parallel imaging include:

- Ultimate spatial resolution of 1 micron at the highest magnification.

- High energy resolution, chemical state imaging.

- Quantitative imaging – the unique spherical mirror analyser and delay-line detector can provide quantitative chemical state images.

- Spectromicroscopy – easy acquisition of spectra from image datasets providing a spectrum at each pixel.

Versatile ESCApe software for acquisition and processing

ESCApe has been developed to make User interaction with the spectrometer as simple as possible, integrating acquisition and processing to fully exploit automation of the hardware. An example of this is the group array analysis capability within ESCApe. This functionality allows the User to drag an area across a sample and define an array of analysis points, from which spectra are acquired. Automated peak identification and quantification allows easy generation of a colour concentration map of identified elements over the sample surface.

Unrivalled instrument automation

The AXIS Supra+ has complete automation of sample handling which sets it apart from any other spectrometer. Auto sample exchange at the end of an experiment allows continuous operation. Unprecedented levels of automation extend to routine maintenance aspects such as computer controlled bake-out and subsequent degassing of filaments.

Automation also includes the X-ray source and monochromator mirror so that calibration and switching between Al Kα and optional Ag Lα excitation sources is completely computer controlled. Furthermore, continued optimised performance is ensured by the motorised multi-position anode.

High throughput sample handling – typical work flow

To guarantee high sample throughput, up to 3 sample holders may be placed on the Flexi-lock sample magazine. An optical image is acquired of each sample holder from which the sample analysis positions are identified during the automated ‘pump’ cycle. An acquisition method is chosen defining all requirements for the data acquisition. A method may define simple spectroscopy or more complex experiments such as sputter depth profiling or angle-resolved XPS. Subsequent analysis from samples on different sample holders can be added to the analysis queue with the automated sample handling system exchanging the sample holder to progress through the analysis queue.

Key attributes of AXIS Supra+ automated sample handling:

- Automated, unattended sample holder exchange.

- High throughput, rapid sample analysis

- Ideal for a multi-User environment

- Sample mounting area up to 7200 mm2 (2400 mm2 x3 sample holders) with maximum sample thickness 19 mm (when using dual height sample holder).