This instrument is capable of high sensitivity quantitative analysis of iron and steel, copper, aluminum alloys and other solid metals, as well as impurities and other elements, thanks to a high resolution monochromator and discharge energy stabilized excitation unit. Excellent operability is achieved with software that enhances instrument monitoring and maintenance support functionality. In addition, this is an energy saving model that significantly reduces energy consumption.

New monochromator design for greater stability

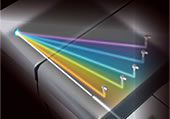

More Precise Analysis Achieved with a High Resolution Spectrometer

Use of a diffraction grating with a wavelength range suitable for ferrous or non-ferrous applications in Paschen-Runge mounting of 1000 mm focal length offers high-resolution measurements over a wide wavelength range. More precise analysis becomes possible by reducing the effect of spectral interference.

Stable and Proven Vacuum Monochromator

Phosphorus and Sulfur, important elements for the analysis of materials, have spectral lines in the vacuum-ultraviolet wavelength range lower than 190 nm.

In this wavelength range, oxygen in the air absorbs light, so the removal of oxygen is required. The PDA-8000 uses a proven vacuum monochromator to provide stable spectroscopic analysis.

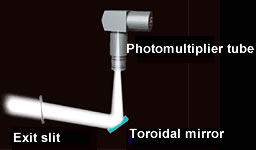

Light Receptor Condensing System

Light passed through the exit slit is focused by a toroidal mirror on the photosensitive surface of a photomultiplier tube. This optical design enables stable measurement.

High Responsiveness to Changes in the Environment

The spectrometer is made from materials that change little with temperature. In addition, by being located in a thermostatic chamber with enhanced thermal insulation performance, changes in the ambient temperature do not affect the instrument, permitting more precise analysis. (Ambient temperature 15 to 30 °C, ±5°C/hour max.)

A Novel Excitation Unit

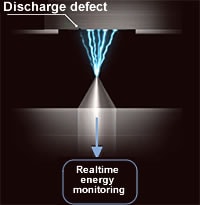

Constant Monitoring of the Discharge Status

A Real-time Energy Monitoring* function monitors the discharge energy consumed between the counter electrode and the sample. The discharge energy is accurately set and controlled, and discharge defects due to the surface condition of the sample can be instantly detected from the discharge energy. The accuracy is improved by eliminating samples with defects from the measurement.

*Patent pending

Supporting Diverse Metal Materials

Many metal materials can be analyzed over a wide range of optimal discharge conditions, such as high-energy discharge for metals like steel with a high melting point, or low-energy discharge for metals like lead and zinc alloys with a low melting point, through the use of a newly-developed discharge energy stabilizing excitation unit.

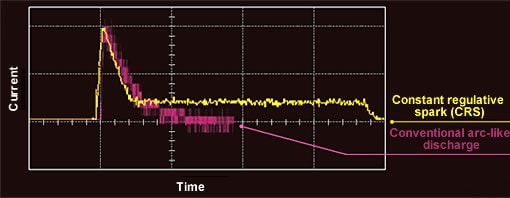

Ultra Trace Analysis of High Purity Materials

Current Regulative Spark* (CRS), capable of stabilizing the current for every pulse, improves analysis sensitivity of trace amounts.

*Patent pending

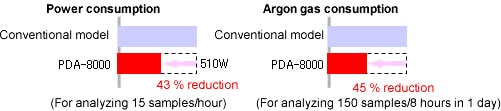

Energy Efficient Design

This energy-efficient spectrometer has a power consumption of 510 W (43 % reduction from our previous Optical Emission Spectrometer).*1 The argon gas consumption has also been reduced by about 45 % as compared to our previous model.*2

*1 For analyzing 15 samples/hour

*2 The consumption for analyzing 150 samples/8 hours in 1 day

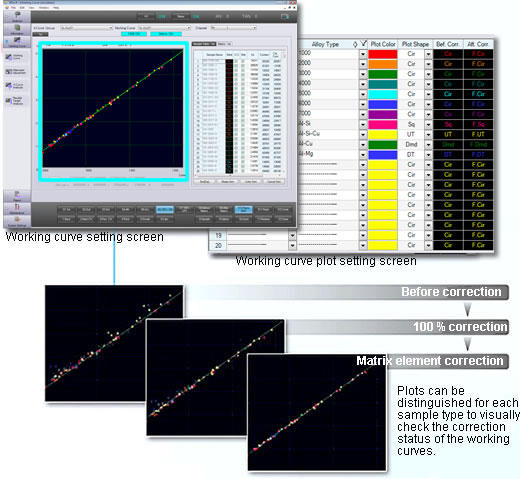

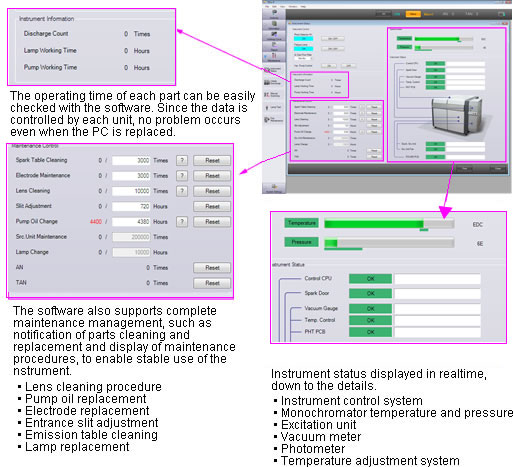

Intuitive Software PDA-R

Fusion of Hardware and Software

Integrating software with the hardware enables reliable instrument management, from control and diagnosis to maintenance.

Fusion of Hardware and Software

The Pursuit of Greater Ease-of-Use, Based on Reliability

A sophisticated, yet operator-friendly design utilizing vast emission spectrometry experience has been produced.

Plots can be set for each sample, which enables more intuitive and easy-to-understand operation.