The EDX-7200 is a flagship model of the EDX series in pursuit of high sensitivity, high speed and high precision. This model supports new regulations and directives for consumer and environmental compliance, such as RoHS/ELV, REACH, and TSCA with full exclusive screening analysis kits.

EDX-7200 for High Speed, High Sensitivity and High Accuracy

High Speed - Throughput Increased by Up to a Factor of 30 –

Equipped with a high-speed circuit that increase the count rate by up to 30 times compared to the former model (EDX-720).

Improved algorithms and improved performance also help to reduce measurement times.

- Comparison of Lead Profiles in Copper Alloys

- Comparison of Chromium Profiles in Copper Alloys

Comparison Using Actual Samples

Sample External Appearance

Repeatability using the EDX-7200 and the previous model (EDX-720) was compared for lead (Pb) in lead-free solder.

- Relationship Between Measurement Time and

Standard Deviation (Variance in Quantitation Values) - Measurement Time Required to Reach the Target Analysis Precision

Extending the measurement time to increase the fluorescent X-ray count can improve the precision (repeatability) of X-ray fluorescence spectrometry.

The EDX-7200 incorporates a high-count-rate SDD detector and a high-speed circuit that achieves highly precise analysis of the target in a shorter measurement time.

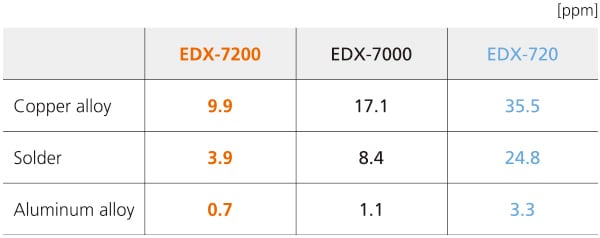

High Sensitivity - Improves Lower Detection Limit by Up to 6 Times –

In metals analysis, the lower detection limit of trace elements in main components has been improved.

Guide of the Lower Detection Limit (300 sec) for Lead in Metals

Note: The detection limit is an example and not a guaranteed value.

High Resolution

High Resolution

- EDX-7200 offers superior energy resolution compared to previous models by incorporating a state-of-the-art SDD detector.

This reduces the effects of overlapping peaks of different elements, enhancing the reliability of the analysis results. - Comparison of Energy Resolutions (sample: PPS resin)

No Liquid Nitrogen Required

The SDD detector is capable of electronic cooling. Since there is no need to use liquid nitrogen, it reduces running costs.

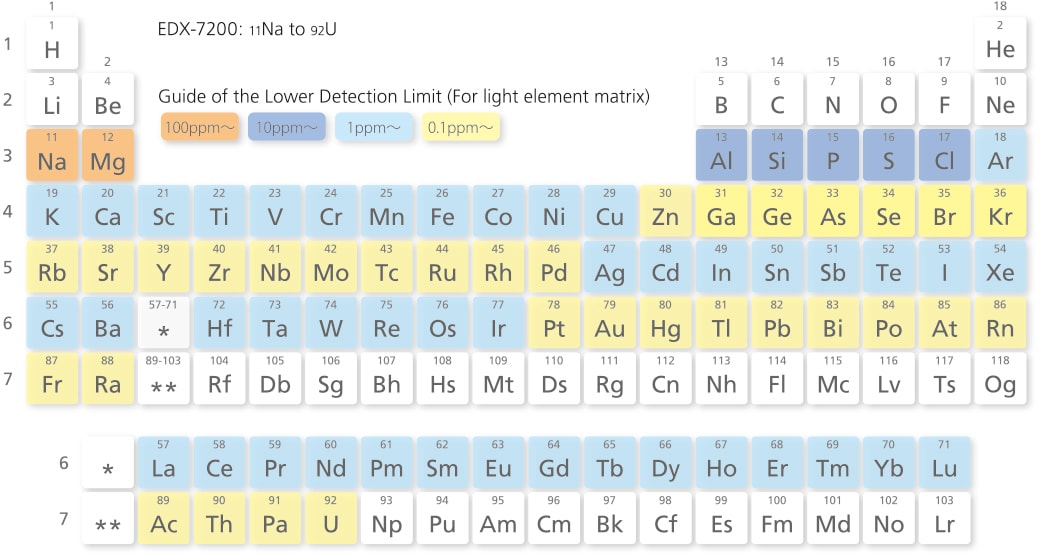

Range of Detected Elements

- An optional vacuum measurement unit or helium purge unit is required to measure light elements (15P and below) with the EDX-7200.

- Lower detection limit varies depending on the sample matrix or coexisting elements.

- Lower detection limit of light elements (20Ca and below) gets worse when the sample cell film is used.

Sample Observation Camera and Collimators

- Automatic collimator switching in four stages: 1, 3, 5, and 10 mm diameter

Select the irradiation chamber from four values to suit the sample size.

Select the most appropriate irradiation diameter for the sample shape: 1 mm diameter for trace foreign matter analysis or defect analysis; 3 mm or 5 mm diameter for small sample volumes.

Sample observation camera included as standard

Use the sample observation camera to confirm the X-ray irradiation area on a specific position.

This is useful for measuring small samples, samples comprising multiple areas, or when using with a Micro X-Cell®.

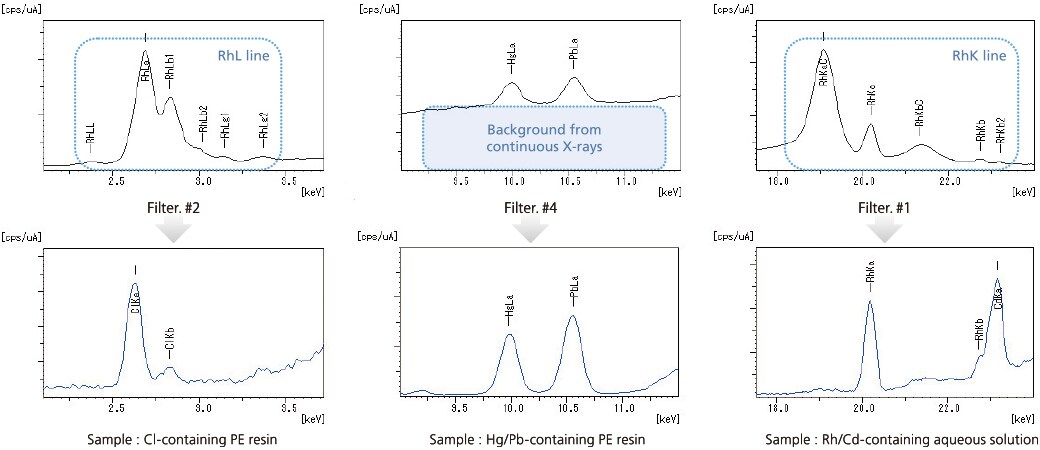

Automatic Replacement of Five Primary Filters

- Primary filters enhance detection sensitivity by reducing the continuous X-rays and the characteristic X-rays from the X-ray tube.

They are useful for the analysis of trace elements.

The EDX-7200 incorporates five primary filters (six, including the open position), which can be automatically changed using the software.

Effect of the Primary Filters

Freely Combine Collimators and Primary Filters

The collimators and primary filters are driven independently and can be combined to address specific requirements. Select the optimal combination from 24 (6 filters x 4 collimators) available options.

Quantitative analysis using the FP method is possible with all combinations.

Vacuum Measurement Unit and Helium Purge Unit (Option)

Sensitivity for light elements can be increased by removing atmosphere. Two options are available: a vacuum measurement unit and a helium purge unit.

The helium purge unit is effective when measuring liquid samples and samples that generate a gas and cannot be measured in a vacuum.

- Relative Sensitivity of Measurements with Helium Purging and in Air

(sensitivity in vacuum = 100) - Profile Comparison in Vacuum and Air

(sample: soda-lime glass)

Helium Replacement Measurement Unit (Option)

- Helium replacement is effective for the analysis of the elements contained in a sample that cannot be placed in a vacuum atmosphere, such as generating liquid or gas. Equipped with a highly efficient helium gas replacement system (Japanese patent No. 5962855), it reduces measurement time and helium gas consumption.

- Profile Comparison in Air and Helium After Purging

(EDX-7200 / sample: sulfur in oil)

- 12-Sample Turret (Option)The addition of the turret allows automated continuous measurements. It improves throughput, especially for measurements in a vacuum or helium atmosphere.

- Calibration Curve MethodA standard sample is measured and the relationship with the fluorescent X-ray intensity plotted as a calibration curve, which is used for the quantitation of unknown samples.

Although this method requires selection of a standard sample close to the unknown sample and creation of a calibration curve for each element, it achieves a high level of analysis accuracy.

This method supports all types of corrections for coexistent elements, including absorption/excitation correction and correction for overlapping elements.

Fundamental Parameter (FP) Method

- This method uses theoretical intensity calculations to determine the composition from the measured intensities. It’s a powerful tool for the quantitative analysis of unknown samples in cases where preparation of a standard sample is difficult. (JP No. 03921872, DE No. 60042990. 3-08, GB No. 1054254, US No. 6314158)

- Automatic Balance Setting Function (Patent pending)

A balance setting is required to use the FP method on principal components such as C, H, and O. The software automatically sets the balance if it determines from the profile shape that a balance setting is required.

Film FP Method

The instrument also offers the thin-film FP method function. The film FP method permits the film thickness measurement of multilayer films, simultaneous film thickness measurements, and quantitative film composition.

When using the film FP method, the substrate material, deposition sequence, and element information can be set.

- Background FP MethodThe background FP method adds scattered X-ray (background) calculations to the conventional FP method, which only calculates the fluorescent X-ray peak intensity (net peak intensity).

(Patent pending : Japanese Patent No. 5975181)

This method is effective at improving quantitation accuracy for small quantities of organic samples, film thickness measurements of irregular-shaped plated samples, and film thickness measurements of organic films.

- Matching FunctionThe matching function compares analysis data for a sample with an existing data library and displays the results in descending degree of confidence.

The library contains content data and intensity data and the user can register each type. The content data values can be entered manually.

Functional Design

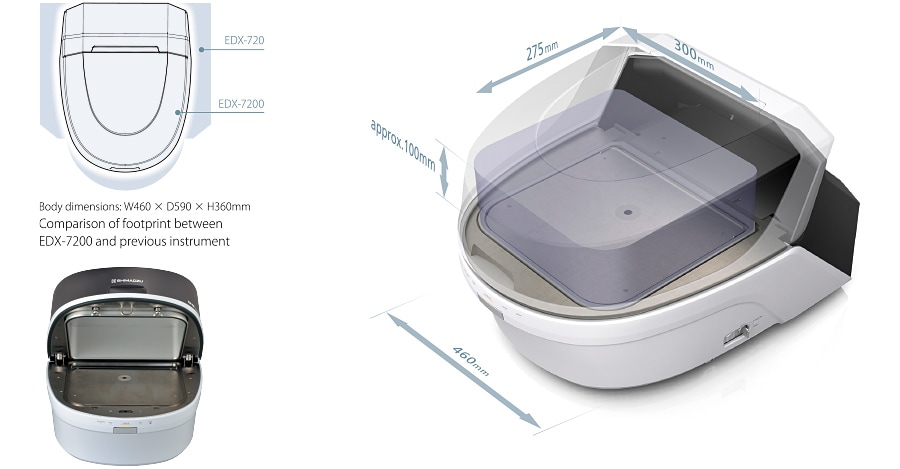

Large Sample Chamber with Small Footprint

Installed width is 20% smaller than the previous instrument (EDX-720) due to its compact body size.

The EDX-7200 can accommodate samples up to a maximum size of W300 x D275 x approx. H100 mm.

High-Visibility LED Lamp

When X-rays are generated, an X-ray indicator at the rear of the instrument and an X-RAYS ON lamp at the front turn on, so that the instrument status can be monitored even from a distance.

PCEDX Navi Software Allows Easy Operation from the Start

PCEDX Navi software is designed to simplify X-ray fluorescence spectrometry for beginners, while providing the feature set and capabilities demanded by more experienced users.

The straightforward user interface offers intuitive operation and provides a convenient operating environment for beginners and experts alike.

Simple Screen Layout

Sample image display, analysis conditions selection, and sample name input on the same screen.

Collimator Switching from the Measurement Screen

Change the collimator diameter while observing the sample image.

The selected diameter is indicated by a yellow circle.

Automatic Storage of Sample Images

The sample image is loaded automatically when the measurement starts. Sample images are saved with a link to the data file.