Taking Innovation to New Heights with Shimadzu X-Ray Inspection Systems The SMX-1000 Plus and SMX-1000L Plus X-ray inspection systems are a further refinement of their popular predecessors, the SMX-1000 and SMX-1000L, which have become the benchmarks of the industry. The operability so well received in earlier models has been further improved, resulting in much simpler and easier-to-see windows. The enlarged fluoroscopic exterior image view provides a new level of visibility. The measurement functions are so much easier to use that results can now be obtained with just a click, and require no complicated parameter settings. New functions such as enhanced region-of-interest display have been incorporated, complementing a wealth of conventional functions including navigation via exterior images, step feed, teaching, and image browsing.

Further Improved Operability

Remodeled windows and an enlarged display with a simple, user-friendly layout ensure the intended operation is performed without guesswork.

Operability (Exterior Image Display)

Large Display and Simple Button Layout for Improved Visibility and Operability

■ Step 1

Sample Placement

Position the sample and activate the X-ray source.

■ Step 2

Positioning via Exterior Image

The external image is acquired with a single click, enabling intuitive positioning of the X-ray observation site with a distinctive, familiar image of the sample.

■ Step 3

Fluoroscopic Observation

Simply click on the X-ray image to enable fine adjustments to the observation site.

Easy-to-view images are obtained with a few simple operations, thanks to image enhancement and contrast adjustment functions.

Furthermore, detailed data analyses can be performed with a mouse click using special measurement tools.

Operability (Reference Image Display)

Large Display and Simple Button Layout for Improved Visibility and Operability

■ Step 1

Sample Placement

Position the sample and activate the X-ray source.

■ Step 2

Positioning via Exterior Image

The external image is acquired with a single click, enabling intuitive positioning of the X-ray observation site with a distinctive, familiar image of the sample.

■ Step 3

Fluoroscopic Observation

Simply click on the X-ray image to enable fine adjustments to the observation site.

Easy-to-view images are obtained with a few simple operations, thanks to image enhancement and contrast adjustment functions.

Furthermore, detailed data analyses can be performed with a mouse click using special measurement tools.

Clear Images

As with earlier models, the combination of flat panel detector with Shimadzu image processing technology leads to clear, distortion-free images.

Features

1. Flat Panel Detector for Clear, Distortion-Free Images!

In combination with the microfocus X-ray tube, this flat panel detector produces clear, high-resolution fluoroscopic images, even at high magnification.

Distortion-Free

Flat panel detector images are free of the distortion typically produced by an image intensifier, ensuring accurate reproduction of surface shapes.

(Gridlines added to show linearity.)

No Shading

Flat panel detector images ensure uniform brightness across the entire image, without shading.

Wide Contrast Range

With a conventional image intensifier, setting X-ray parameters to allow observation of high-absorption interior motor parts causes the image’s low-absorption peripheral plastic parts to appear white, making them difficult to observe.

With the flat panel detector, however, a few simple brightness and contrast adjustments allow the operator to efficiently observe both the motor interior and peripheral plastic areas, even on images captured using a single set of fixed X-ray parameters.

This improvement in visibility is possible thanks to a 16-fold increase in the amount of information in 12-bit images produced by the flat panel detector, compared to 8-bit images from an image intensifier.

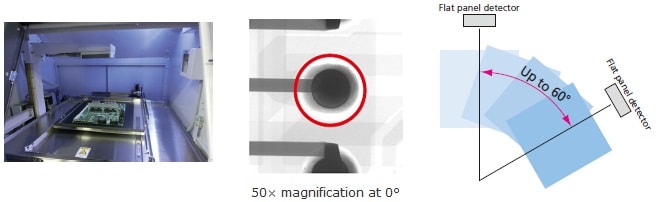

2. Fluoroscopy at up to a 60° Angle!

With a tilt angle of up to 60°, the flat panel detector enables fluoroscopy over an extensive range, while maintaining constant magnification.

Tracking minimizes displacement of the fluoroscopy position, even when the C-arm is tilted, ensuring you never lose track of observation points.

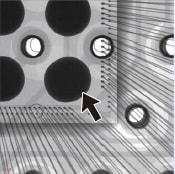

Inclined Fluoroscopy

The flat panel detector with a tilt angle of up to 60° enables fluoroscopy over an extensive range while maintaining constant magnification, so defects that are undetectable with vertical fluoroscopy can be detected.

Flat panel detector not tilted

Flat panel detector tilted at 60°

Solder ball joint defects that cannot be identified at 0° (when viewed from top) can be easily identified when viewed at 60°.

Easy Measurements

Troublesome measurement parameter settings are automatically optimized, and thanks to our proprietary image-processing technology, measurement results are now obtained with simple mouse operations.

- BGA Measurements

- Area Ratio Measurements

- Wire Sweep Ratio Measurements

- Dimension Measurements

- Three-Point Measurement

Measurement Functions

No Need for Complex Parameter Settings

BGA Measurements

BGA (ball grid array) bump diameter and void ratios can be measured.

Shimadzu’s proprietary image processing algorithm has significantly simplified complicated parameter settings.*

You can save multiple settings, and then call up different settings when measuring different inspection targets.

* Manual adjustments may be required depending on the sample.

(Measurable Items)

- Total void ratio

- Maximum void ratio

- Bump diameter

- Bump roundness

Area Ratio Measurements

Measure area ratios for die bond and solder paste wettability.

Thanks to our proprietary image processing algorithm, complicated parameter settings are no longer required.*

You can save multiple settings, and then call up different settings when measuring different inspection targets.

Pass/fail evaluations can be performed based on area ratios.

* Manual adjustments may be required depending on the sample.

Wire Sweep Ratio Measurements

Specify both ends of a bonding wire and the point of maximum sweep to measure the wire sweep ratio.

Pass/fail evaluations can be performed based on the wire sweep ratio.

Dimension Measurements

Measure the distance between two points, as well as angles and curvatures.

Correction data is internally calculated to match the fluoroscopy magnification rate, enabling efficient dimension measurements.

Three-Point Measurement

This function is useful for measuring the distance between electrodes in Li-ion batteries.

If a reference line is drawn from an arbitrary point, and a second line is drawn from the same point but perpendicular to the reference line, then the system can measure the distance between this second line and another arbitrary point.

The specified book id does not exist.