Easily Obtain Images with High Sensitivity and High Spatial Resolution

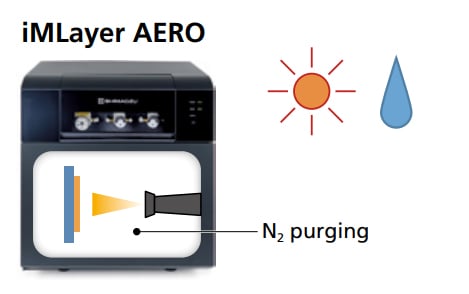

The iMLayer™ AERO incorporates a sample stage that moves at a controlled rate while maintaining the same distance from the spray nozzle, enabling stable matrix spraying.

Over multiple strokes, the sample becomes laminated with fine matrix crystals, enabling high sensitivity and high spatial resolution.

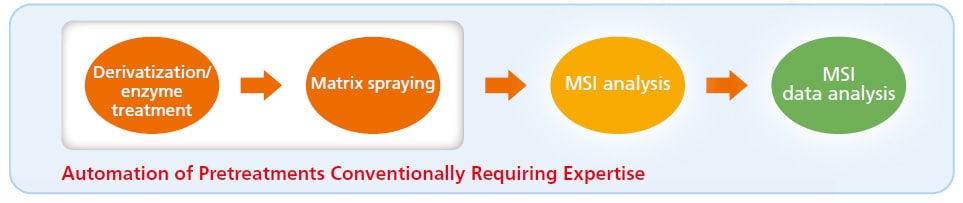

Work Flow

Imaging with High Reproducibility

Humidity Control

Humidity does not impact matrix deposition because the atmosphere within the spray chamber is replaced before pretreatment. Spraying can be performed under more stable conditions than with a hand spray.

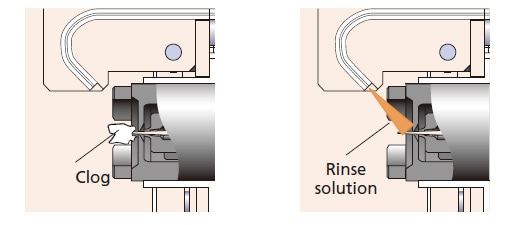

Clog-Free Reagent Delivery

If the matrix clogs the nozzle tip, the spray becomes unstable, which can lead to lower reproducibility. The rinsing mechanism allows for clog-free, stable spraying, which enables high reproducibility in MALDI analyses.

Both Sensitivity and Spatial Resolution Achieved

Excellent Spray Performance

The standard protocol provides sensitivity on par with a hand spray along with improved resolution, homogeneity and reproducibility

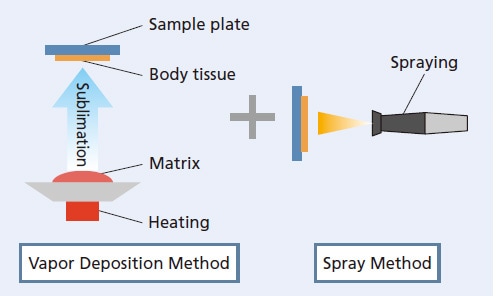

Two-Step Vapor Deposition

To acquire high spatial resolution (5 to 10 μm) images and increase sensitivity, a two-step vapor deposition method can be implemented in combination with the iMLayer matrix vapor deposition system has been developed.* This unique experiment can only be implemented using Shimadzu sample preparation solutions.

* Patent No.: JP6153139 and JP6183779

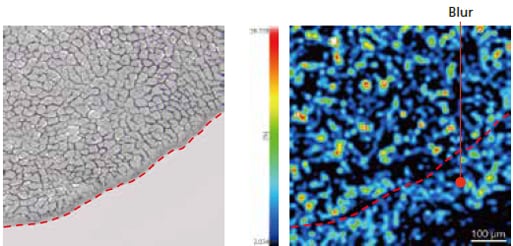

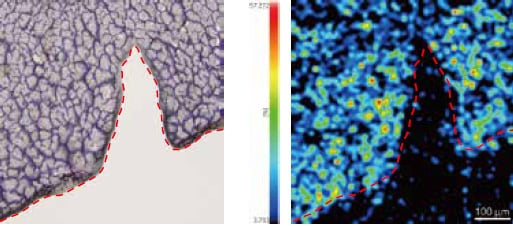

Two-Step Vapor Deposition Allows for Very Fine Images with Minimal Blur

Hand Spray

- Matrix:9-AA

- Volume used:200 μL

Two-Step Vapor Deposition1 step:iMLayer(vapor deposition method)

- Film thickness:1 μm

2 step:iMLayer AERO(spray method))

- Solution delivery volume:120 μL/min

- Stage speed:70 mm/sec

- Laminating layers:4

Applicable to Pretreatment Other than Matrix Coatings

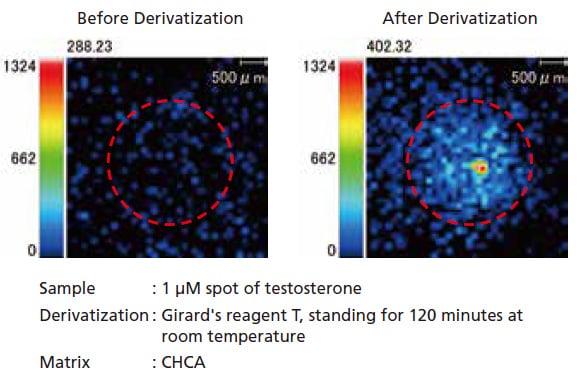

Derivatization Treatment