Highly advanced on-line TOC Analyzer excels in a wide range of applications

The TOC-4200 is a high-performance on-line TOC analyzer, based on the proven 680°C Catalyst-aided Combustion technology. This established technology is featured in a large installed base of Shimadzu Total Organic Carbon Analyzers throughout the world, and has been applied to a broad field of industries.

Diverse Applications

Supports monitoring TOC removal rate based on EPA Regulations

- Calculates TOC removal rate based on the United States EPA regulations

(Part IV 40 CFR Part 9, 141 and 142, 1998)

(when a 2- or more-stream switching option is provided)

Total pollutant load control regulation applications (organic pollution load) -Japanese regulation

- Converting the measured TOC values allows applications to COD total volume control. (*1) TOC → COD conversion functions are installed as standard.

- Reading flow rate signals from a flow meter (*2) permits COD load conversion calculations.

Wastewater treatment plant influent (upstream monitoring) and effluent

- Measurements at a short measuring cycle (4 minutes minimum) rapidly capture dramatic changes in organic matter or abnormal effluent.

- The powerful oxidation capacity of a combustion-type analyzer can detect organic matter that cannot be captured using a UV meter.

- The short measuring cycle and powerful oxidation, combined with switching between up to six flow lines, offer detailed monitoring of treatment plants.

Monitoring of river water sampled at water purification plants and treated water (tap water)

- Monitoring changes in river water quality due to rainfall and other factors to provide control indicators for treatment processes.

- Permits simultaneous monitoring of treated tap water.

Plant water (washing water, cooling water, recovered water, boiler water, condensate, etc.)

- Continuous monitoring of water used in a plant.

- Continuous monitoring of pure boiler water assists in the detection of anomalies, such as damaged pipes.

- The short measuring cycle (4 minutes minimum) of the combustion-type TOC analyzer achieves more rapid detection of anomalies.

*1 The TOC-COD conversion formula must be determined separately.

*2 With attached option

TOC-4200 is granted MCERTS accreditation

The TOC-4200 online total organic carbon analyser has been granted MCERTS accreditation based upon the performance standards and test procedures set for continuous water monitoring equipment.

MCERTS is the Environment Agency of England & Wales (UK) Monitoring Certification Scheme. It provides the framework for businesses to meet quality requirements. Compliance with MCERTS gives the Environment Agency confidence in the monitoring of emissions to the environment.

MCERTS is quickly becoming an internationally required performance and reliability standard by companies and authorities around the world that want to ensure that they are doing their utmost to protect the environment around them by using equipment with this accreditation. Requirements to gain this certificate include laboratory testing and a 3-month field test under real conditions. The TOC-4200 achieved 100% uptime in the field test highlighting its robustness.

The TOC-4200 is the only online TOC analyser that utilises catalytic combustion oxidation technology, with MCERTS accreditation, available on the market. This technology is a clear advantage for anyone interested in analysing water and effluent that has a high salt content, suspended solids, or particulates, and the most complex of organic compounds.

The certificate (MC160311/00) covers the ranges, 0-100, 0-500, 0-1000 and 0-10,000 mg/L of Total Organic Carbon. Utilising the automatic conversion function of the TOC-4200 to determine COD values.

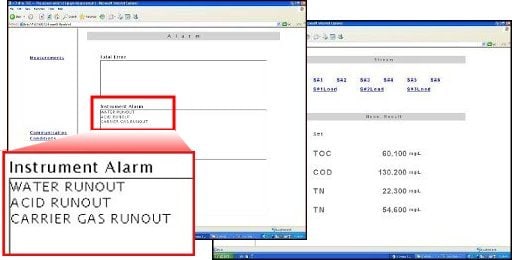

Support for New Means of Communications, Enhanced Data Handling

Compatible with digital bus standard

- Instrument operation, readout of measured values, and checking for alarms can be performed via the RS-485 or RS-232C (option). This function is convenient when managing multiple instruments.

Control sample measurements

- Periodic measurements of pre-selected control samples. This can be used to monitor the condition of the instrument. Automatic calibration can be performed when a certain reference value is exceeded.

Web-based monitoring (option)

- Installing an optional board allows connection of the instrument to a network. The optional board offers web-server functions, allowing real-time browsing of measured values and alarms with a Web browser.

Support for a Wide Range of Samples

From pure water to heavily polluted water

- Measurement ranges from 5 mgC/L full-scale to 20,000 mgC/L full-scale.

An option can be attached to support high-sensitivity measurements to 1 mgC/L full-scale. - The pretreatment unit for heavily polluted water incorporates a unique washing function and special operation sequences to control blockages and biological contamination. This reduces the maintenance frequency.

Automatic dilution function

- TOC-4200 offers sample automatic dilution functions (×2 to ×50) as standard.

- When measuring an acid, strong alkaline, or inorganic salt sample that may damage the instrument or consumables, the effect can be alleviated by diluting the sample.

- A single high standard can be auto-diluted to make a multi-point calibration curve for laboratory time saving effort.

High-salt sample combustion tube kit

- When measuring samples with high levels of inorganic salt, such as seawater, the inorganic salt can accumulate inside the combustion tube and cause physical blockage or deterioration of the combustion tube. This kit extends the tube-replacement period approximately ten times as compared to a normal combustion tube.

Permits TOC measurements that match the sample’s characteristics

- TOC measurement by acidify and sparge TOC also know as non-purgeable organic carbon (NPOC)

- TOC determination by difference between total carbon (TC) and inorganic carbon (IC)

TOC = TC – IC (requires option) - TOC determination by addition method of NPOC and purgeable organic carbon (POC)

TOC = NPOC + POC (requires option)

Range of pretreatment units to match a sample’s characteristics

- Pretreatment units are available for applications from pure water to heavily polluted water.

- Reduces instrument maintenance frequency.

- Switch between measurement points in up to six flow lines. More economical since the need for multiple instruments is eliminated

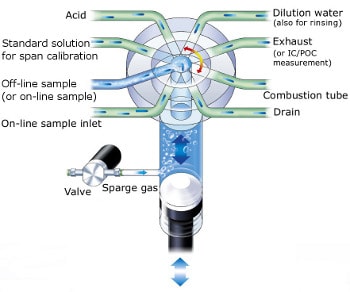

Reliable sample injection system

- A single unit performs sample intake, discharge, dilution and injection.

- Automated sample acidification and sparging.

- Highly reliable ceramic 8-port valve used to switch flow lines

Low Maintenance, Low Running Costs

Carrier gas purification function as standard

- A carrier gas purification function is installed as standard for 24-hour continuous operation by the analyzer. Purifying instrument air or compressor air in a facility to produce carrier gas significantly reduces running costs.

N2 carrier set

- Compressed air is normally used as the carrier gas source but high-purity nitrogen gas can be used as the carrier gas as well. Convenient when a nitrogen gas centralized pipe is available in a facility (optional).

Water pump control functions

- Pumps sample only when necessary to save pumping energy and reduce maintenance.

- Accommodates low flow rates and restricted sampling timing.

Notification of replacement periods

- When the time to replace a consumable approaches, a pop-up window notifies the operator and gives instructions.

- Combining the contact outputs and other warning outputs simplifies consumables management.

Advanced Operability

Color LCD touch screen

- Easy-to-view color LCD

- Easy touch screen operation

- Large buttons

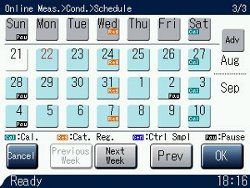

Calendar

- The calendar simplifies scheduling for automatic calibration, instrument sleep function, control sample measurement, and catalyst regeneration (up to 14 weeks). Batch inputs can be made by specifying a day of the week.

Hot sample measurement

- Off-line sample measurements can be performed in the standby time periods, even during on-line operation.

Generous data storage capacity

- The instrument internal memory can store 20,000 measured values (equivalent to one year’s data at a 30-minute measuring cycle), 100 calibration values (equivalent to weekly automatic calibration over one year), and history of 100 alarms.

- Six calibration curves can be saved for each measurement type (TC, NPOC, IC*, POC*, and TN*) to simplify switching between operation conditions.

- USB port fitted as standard below the touch screen. Measured values and measurement conditions can be saved to USB memory. Measured results are saved as CSV files to simplify the management and processing of large quantities of data.

*Optional