TG/DTA Simultaneous Measuring Instrument

This instrument varies the sample temperature in accordance with a program and simultaneously measures the change in mass of the sample (TG) and the temperature difference between the sample and a standard substance (DTA). An analytical balance mechanism (Roberval mechanism) offers high reproducibility and allows worry-free operation even for measuring sample weights. Two models are available for different maximum measurement temperature requirements-the DTG-60 (max. 1,100 °C) and the DTG-60H (max. 1,500 °C). Corresponding DTG-60A and DTG-60AH models with a built-in autosampler are also available to automatically measure up to 24 samples.

High-Sensitivity and High-Accuracy Measurement

High-accuracy Roberval mechanism top-loading balance system

The Roberval mechanism has been adopted, so that the sensitivity does not change due to changes in the center of gravity of the sample caused by melting, etc.

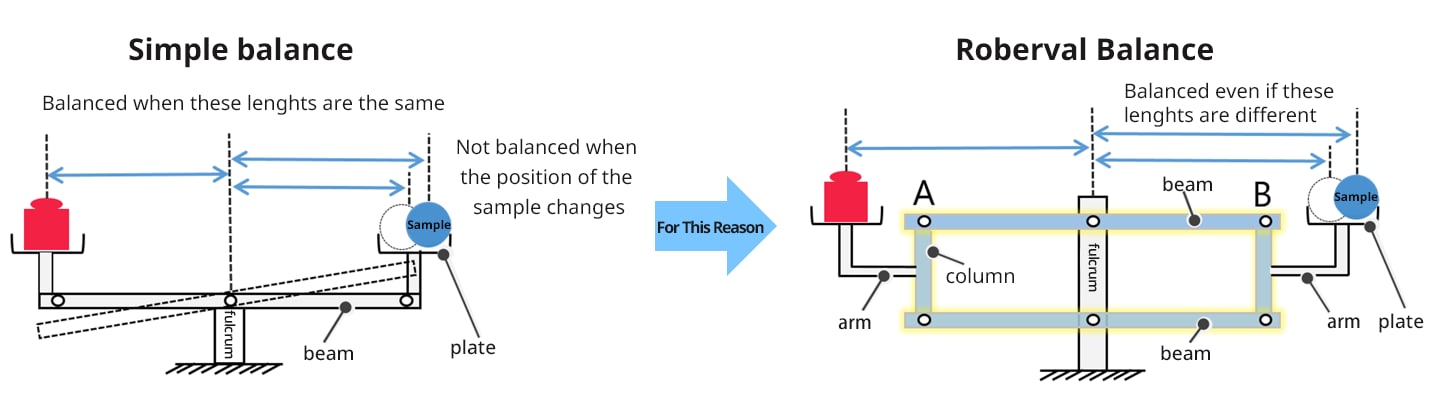

What is the Roberval mechanism?

Regardless of where the sample is placed in the detector pan, the sensitivity of the balance remains constant. The sensitivity does not change due to changes in the center of gravity of the sample caused by melting or expansion due to heating.

With a simple balance, the measurement varies depending on the position in which the sample is placed. There is a possibility that the result will change every measurement, so the reproducibility is low. When the beam is heated in the furnace the distance between the fulcrum and the sample changes due to thermal expansion, so the measurement changes. If the center of gravity of the sample varies during measurement due to melting or expansion caused by heating, then the measurement will change.

On the other hand, the Roberval balance has a parallelogram frame structure with freely moving sides, as shown in Fig. B. If pans are placed on its vertical beams and the sample and weight are placed on top of these pans, they will be balanced regardless of where the sample and weight are placed if their masses are the same. The sample may be placed anywhere on the pan.

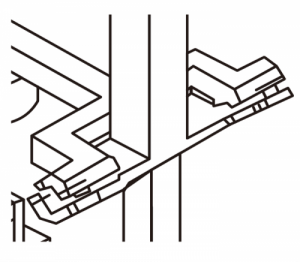

Light Fulcrum

The fulcrum is a thin alloy band with a very small temperature coefficient, configured into an X-shape. This fulcrum is lightweight and has very little friction and resistance, enabling the construction of a high-sensitivity balance, which is also very resistant to vibrations.

Supports Various Types of Measurement

Flow channels for reaction gas provided

With TG/DTA measurement, qualitative and quantitative analysis, the study of reaction mechanisms, and evaluation of thermal resistance can be carried out by observation of various types of reactions and interactions between the sample and special atmosphere gases. With the DTG-60 Series, various applications are supported by configuring individual flow channels. There is one gas inlet, so the gas can be led directly to the sample, and time is not required for the reaction.

Wide range of thermogravimetric measurement

The thermogravimetric (TG) measurement range is broad at ±500 mg, with a weighing capacity of 1 g (including tare weight), so it can be used for diverse measurements.

Automated Functions Increase Throughput

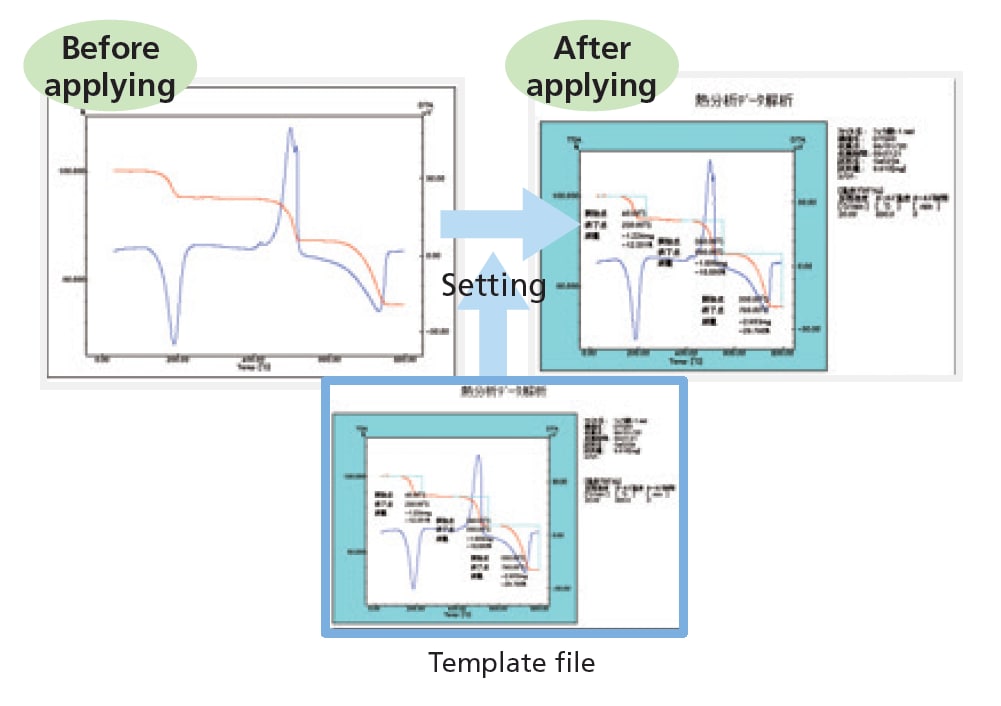

The analysis is simple with the automatic analysis function: `Template Function`

Corrections, analysis, and layout setting of reports can be carried out automatically using the unique `Template Function.` This can be used not only during analysis but also prior to measurement. It will be automatically applied when the measurement is completed and saved.

Shorter analysis wait time

The built-in furnace cooling fan starts automatically after the measurement is complete.

Also, it is possible to stop the fan at a predetermined temperature (setting can be varied), so the next measurement can be started immediately.

Software enables easy operation for everything from measurements to data analysis

LabSolutions TA workstation software ensures all steps from measurement and data analysis to report generation can be performed smoothly using intuitive operations. It also allows the instrument operating status to be confirmed at a glance.

Optional software is also available for supporting a variety of specific measurement parameters.