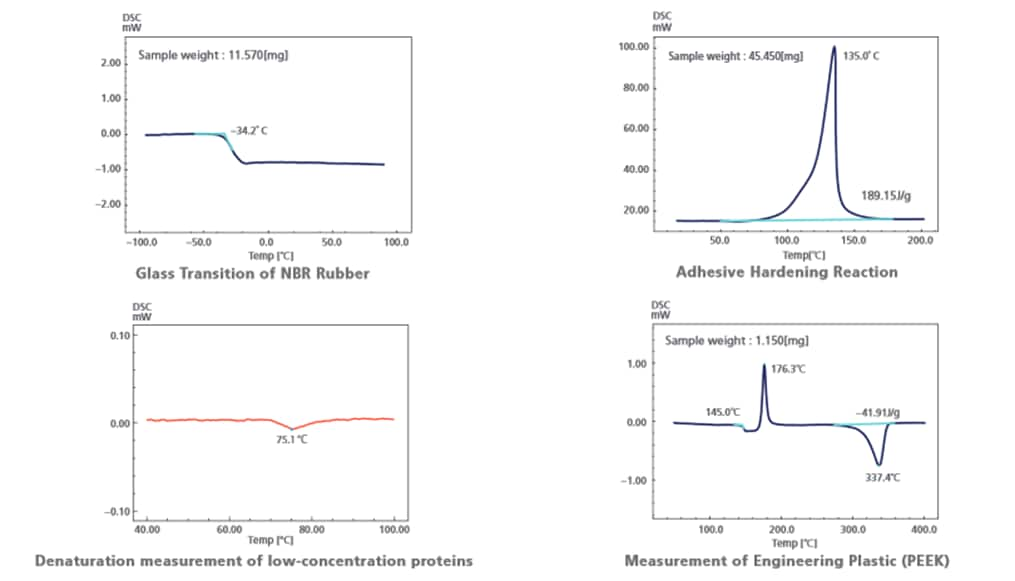

DSC-60 Plus addresses the various DSC applications.

DSC (Differential Scanning Calorimeter) is an indispensable thermal analyzer for materials characterization in R&D and quality control applications in such areas as polymers, pharmaceuticals, electronic parts , foods , etc . It offers the sensitivity and easy operation required for the development of high-performance, highly functional new materials.

A DSC-60A Plus model with a built-in autosampler is also available for measuring up to 24 samples automatically.

By overlaying temperature-modulated results onto results obtained by increasing the temperature at a constant rate, Temperature Modulated DSC (Option) can easily measure specific heat, or can measure multiple phenomena that could not be separated using standard DSC systems.

Enables high-sensitivity measurements at temperatures ranging from ultra-low to high.

The DSC-60 Plus series achieves a stable baseline throughout its entire measurement temperature range (-140 to 600 °C) and offers the highest DSC sensitivity levels. The series also provides calorimetric measurement over a wide ±150 mW dynamic range.

Enables a wide variety of measurements using simple operations.

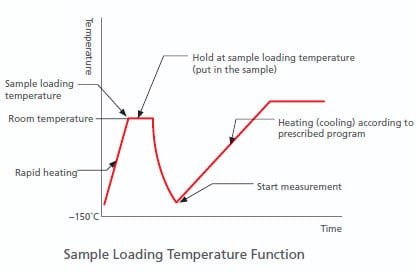

DSC-60 Plus series enables easy measurement of samples that need to be measured below room temperature by filling a standard cooling bath with liquid nitrogen.

The sample loading temperature function only heats the region around samples when they are replaced during successive measurements. The temperature is set to allow quick resumption of measurement without moisture condensation.

Temperature Modulated DSC (TM-DSC) (Option)

By overlaying temperature-modulated results onto results obtained by increasing the temperature at a constant rate, TM-DSC can easily measure specific heat, or can measure multiple phenomena that could not be separated using standard DSC systems.

If glass transitions, enthalpy relaxations, and other reactions overlap, separation is impossible with standard DSC measurements. Using TM-DSC, however, enables separation of these phenomena.

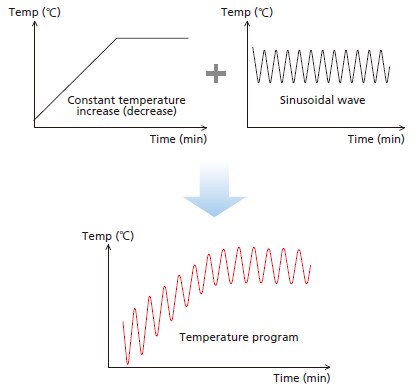

What Is TM-DSC?

By overlaying temperature-modulated results onto results obtained by increasing the temperature at a constant rate, TM-DSC can easily measure specific heat, or can measure multiple phenomena that could not be separated using standard DSC systems.

This program can control the temperature by overlaying a sinusoidal modulation over a constant temperature increase (or decrease).

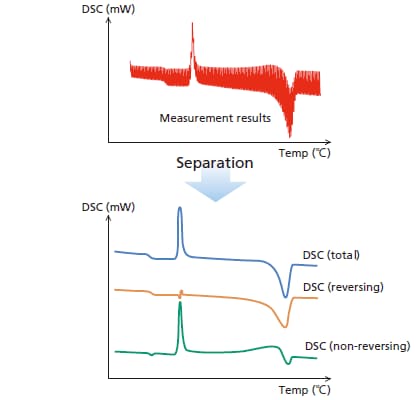

Three types of heat flow data can be obtained by post-measurement data analysis.

(1) DSC Signal (Total)

Indicates the total heat flow.

This is the same as the heat flow obtained from standard DSC systems. It is obtained by deleting the modulated component from the data obtained by TM-DSC.

(2) DSC Signal (Reversing)

Indicates the reversing heat flow.

This component of the heat flow tracks the temperature modulation, and is equivalent to measured heat. It is obtained from the modulated component of data obtained by TM-DSC.

(3) DSC Signal (Non-Reversing)

Indicates the non-reversing heat flow.

This is the component of the heat flow that does not track the temperature modulation. It mainly appears for thermal processes that progress spontaneously, such as crystallization, curing, and enthalpy relaxation. It is obtained by subtracting the reversing signal from the total signal.

Software enables easy operation for everything from measurements to data analysis.

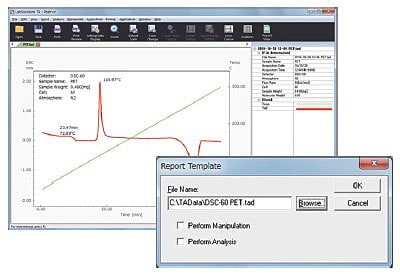

LabSolutions TA workstation software ensures all steps from measurement and data analysis to report generation can be performed smoothly using intuitive operations. It also allows the instrument operating status to be confirmed at a glance.

Optional software is also available for supporting a variety of specific measurement parameters.

Easy-to-use data analysis functionality improves productivity.

- Automatic manipulation and automatic analysis functions in template format

- Measurement result reports are automatically prepared

When the template function is used, manipulation and analysis can be automatically performed. By configuring the template in the acquisition program prior to measurement, automatic analysis and report preparation can be performed.

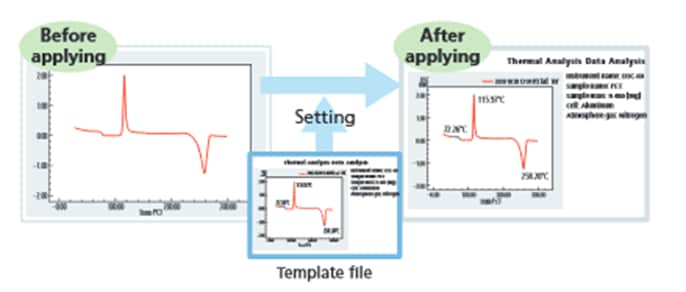

Automatic analysis using the “Template Function”

Corrections, analysis, and layout setting of reports can be carried out automatically using the unique “Template Function.” This can be used not only during analysis, but also prior to measurement. It will be automatically applied when measurement is completed, and saved.

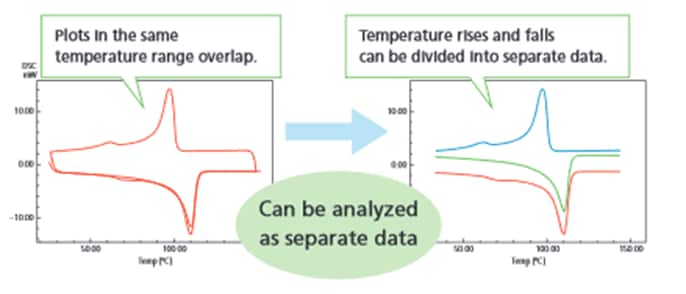

Temperature change data can be analyzed with ease

Data on repeated temperature increases and decreases can be treated as independent data using the “Analysis Range Setting Function,” so analysis can be carried out simply. Using this function, data related to repeated temperature increases and decreases can be divided into separate data.